I’m trying to assemble my newly-rebuilt door into the hole in the body, basically. I’ve assembled the rear aluminium door shut plate to the timber end piece, and have checked it latches OK. It seems to be holding the door panel too far rearward, i.e. too tight to the B pillar. Should there be shims under the striker on the B pillar? There are none on mine so shims would help greatly. The door fit was non-existent when I got the car as the hinges had been mullered to death by a previous owner due to seizure and the door was flopping loose around the top hinge only, so I don’t know what was there before.

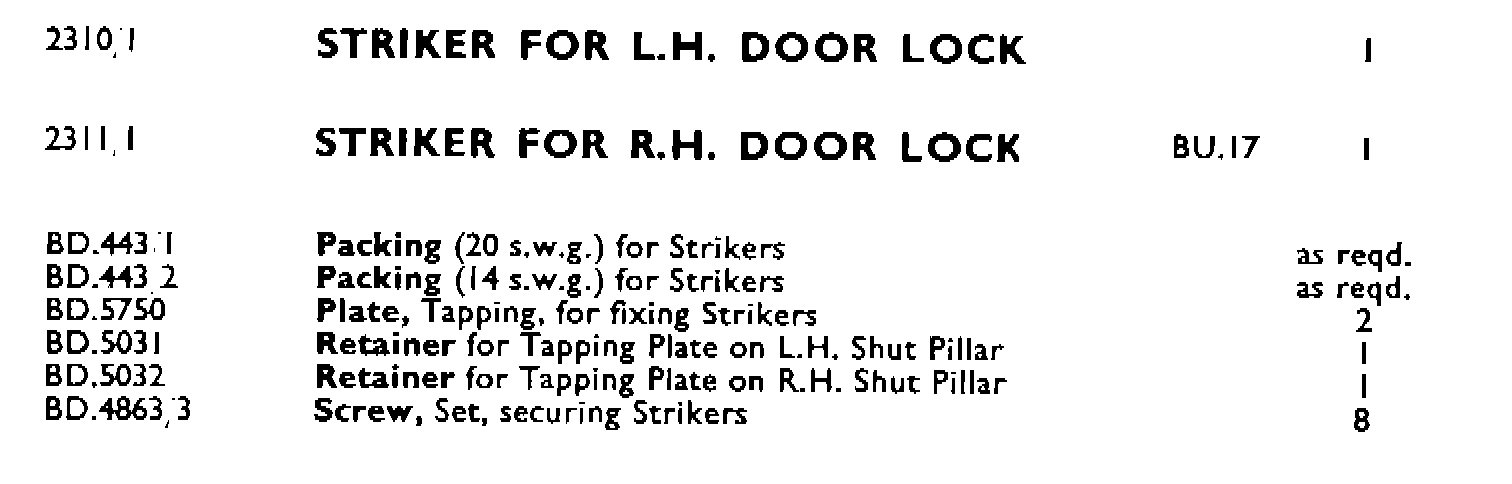

If there are shims here (no pictures in the Jag parts book unfortunately), could someone tell me what thickness they should be, and what thickness a typical door striker shim pack is likely to need?

Edit - and would the shims be just rectangular plate, in aluminium?

From the 140 book.

Fortunately the 120FHC book gives the thicknesses.

Probably steel, most packings are.

Hmm, 443 is a pretty low BD number. I bet it was used on a previous model. I’ll see if I can find it.

Thanks Rob, that’s what I wanted to know. Looks like 1mm or 2mm then, presumably aluminium and I guess the same shape as the striker base with hole. Anybody got examples of how many might be used, to what thickness?

Shame the XK parts book (well, the 140 one, at any rate) is so poor as to be relatively useless. I don’t need a list of numbers, I need to know what the parts look like - you can’t beat an exploded diagram! I’ve restored lots of cars over the years and often the parts book is more use than the manual. Not so here!

My 1938 SS saloon has the same strikers, and Mark IVs also used this same striker and presumably shim or packing. It looks like I have one out of 4 doors and it is made of steel, not aluminum.

I don’t see any on my 120 FHC so maybe they were not always needed.

Hi guys,

My ‘56 has packing under the left striker, and none under the right side striker.

On the left, the packing is actually two pieces, one near the top, one at the bottom. I seem to remember each packing piece is sort of rectangular, with a C shaped recess in one end, to provide clearance for that cylindrical portion that goes through the hole in the body.

Each packing piece is around .063” thick.

The second picture shows an additional layer of thinner packing right up against the body, which I think I made of sheet metal and put in there a while back to space the striker out a little more.

I’m pretty sure the thicker packing, presumably original, was steel and not aluminum.

Easy to make, just cut out rectangles, grind a C shaped cutout in one end, drill two holes in each piece for the screws, done.

Thanks Phil, very helpful. My Cobra has the same strikers and uses spacers as required - I wondered about the 140 because it appears to have had none for some time. It was resprayed a long time ago, completely covering the strikers (nice) and the door alignment was non-existent, presumably being like this since the hingepins were snapped off by welding. So I had no points of reference to work with.

Does anyone know what the original surface finish of the spacers would be ?

I think the spacers would have been installed after the doors and body were already painted.

So I am guessing the original surface finish of the spacers should be a blackened finish, sort of like the suspension caster adjustment shims?

Or maybe black paint ?

Attached is a photo fo a set of original door striker spacers. This year’s winter project is to adjust the doors, so I took the strikers off. My car is a '53 DHC, built in June, 1953. The shim with the rounded corners goes on the top. The one with the square corners goes on the bottom. These are painted body color. The number of shims varied to get the striker in the right place, so fitting it back in is sort of a trial and error PIA.

The beautiful chrome striker and the chrome plated oval head machine screws were also painted body color. This part of the painting was not done with a great degree of care.

As an aside, once I got the door strikers off, the backing plate was pretty well toast, so I’m in the process of having some made from stainless steel 3/16". The backing plate is the same for each door. The machine screws are 2 BA. This thread is very close to 10-32 and a 10-32 thread will fasten without difficulty to the 2 BA mating thread. Getting oval head, chrome, slotted machine screws in 10-32 is not trivial, but they are wicked expensive. So I’m having a box chome plated.

If anyone would like a backer plate or a quantity of the machine screws, let me know: cliffordlewis66@gmailcom. The backer plates should be about $29 each. They will be water-jet cut with ⅛" holes that you can drill out and tap for the 10-32 or for the 2 BA. I can get you the backer plates drilled and tapped for the 10-32 thread with a set of 10/32 chrome, oval head slotted machine screws for about $39.

Cliff