Looks mouse to me, clutch stops are welded to the frame.

I don’t think so , I believe they are part numbers

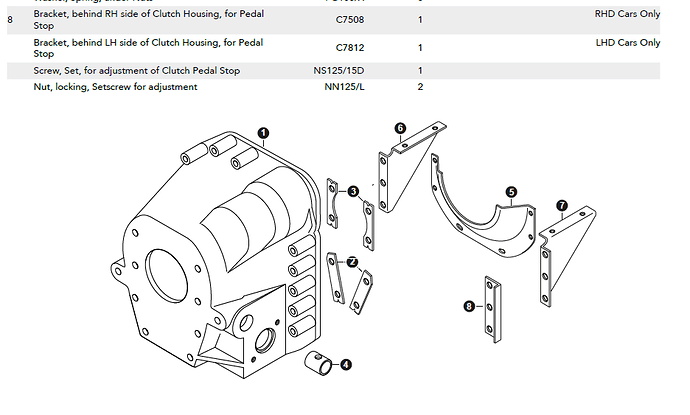

C7812 LHD

C7508 RHD

My (LHD) bolt is off set away from the gearbox , in Viarts book the RHD bolt looks inline with the gearbox bolts .

Its item 8 on here.

Would the offset on LHD be because item 29 is offset but is used on both RHD and LHD?

That seems to explain it . I haven’t yet worked out which different bits I need to convert to RHD

My mistake, XK120 has stops welded to frame.

See XK140 stops at SNG Barratt PG 65

Tried to find this on SNG’s website, no luck - just ‘unavailable NLA’ and no pictures.

Go to catalogues, XK140, Download digital copy, English, click the download icon in the upper right corner, Open with Adobe Acrobat. You can save it to your computer.

Thanks Rob, found it.

Great topic. So good that I decided to take a look at my ‘56, and I ended up finding that it has no clutch stop bracket. Must have gotten lost along the way.

Looks like I should be able to make one up ok, but is it correct that there is a nut welded on one end of the bracket ?

Anyone know the thread size and length of the nuts and adjusting bolt? Would it be a Bees bolt?

Also, would the bracket be around .140” thickness, like the engine mount brackets?

Thanks in advance for any dimensions.

No wonder my ankle ends up being held flexed backwards way too much when trying to not ride the clutch.

Mickey…

Hey Jim,

Thanks a bunch for the diagram and dimensions. Exactly what I need. My ankle will hopefully benefit from this.

Don’t worry, I’m in Canada, which has converted over to the ‘metric system’ of measurement way back in the 1970s, but the regular Imperial system of units didn’t go away and is used as well. Back in those days Canadian industry still had some manufacturing capability, and factories couldn’t afford to replace existing Imperial dimensioned machinery.

Well, you can have a third of a foot, but there’s no nice and neat third of a metre…

Well, I finally have begun making a clutch stop bracket, thanks again Jim and everyone else for providing dimensions for a left hand drive version.

As mentioned before, I didn’t even know the clutch stop bracket was missing from my car, and ended up driving it, all the while having to put up with the clutch pedal returning way too far rearward, almost coming back to the seat. Made it uncomfortable for anyone whose left leg doesn’t flex like a frogs leg, to actuate the clutch pedal, but luckily for me I didn’t even know the difference.

Anyhow, upon crawling under the car to make sure the proposed bracket would fit, I discovered that Mickey Mouse is very much present in my garage…take a look… I completely forgot that at some long forgotten time in the past, I had rigged up this Mickey Mouse arrangement…

The spring and brass wire gently cause the lever on the clutch pedal shaft to tend to move back toward the lever on operating shaft, thus reducing much of the unwanted rearward play of the clutch pedal…making the car much more comfortable to drive.

Note that there is still some play, and the throw out bearing still is not touching the clutch when in the released position.

So now I will be able to replace the home made arrangement with a representation of the real thing.

Here is a the start anyway…I usually end up having to: measure twice, cut three times.

Bracket starts as a flat plate, now cut slightly oversized, which bends easily in press brake to form L shape cross section.

Time to cut it again and drill some holes.

Then I can check it for fit, then cut it again, to hopefully the final size.