I know there are several threads regarding unusual engine noise but none of them seem to exactly match my problem. I have a 3.8L six in an XK150; at cold startup the Oil pressure comes up quickly and the engine sounds perfect then about 1 or 2 minutes later it starts to make a fairly loud tapping noise; I’ve pulled the HT lead to each plug with the engine running and don’t detect any change in the noise so I believe its not rod or main bearings or piston slap. As the engine warms up the noise gradually disappears. I’ve had the cam covers off thinking it might be a tappet guide hitting a cam lobe but I don’t see any evidence of that; a LOT of oil sloshing on inlet side and not nearly as much on exhaust side. The engine was professionally rebuilt by previous owner at a competent shop (per invoices) many years ago but I don’t think there are more than 10,000 mls on it since. Any thoughts out there?

Listen with a mechanic’s stethoscope or a long screwdriver handle in the ear, touching the tip all over, to identify exactly where the noise is coming from.

Oil sloshing should be about equal on both sides. Maybe this competent shop didn’t put in the right hollow bolt in the exhaust side oil feed.

I’ve got the same issue with my Series II XJ. mine was the bottom end. I layed down next to the car when it was running, and I could hear the rattle more distinctly. It’s parked right no until I can get this IRS into the back end of one of my XJ’s so I can pull the engine and see what’s what.

If you pull the breather or the oil filler cap while it’s running does the noise get louder? or more pronounced?

Also, keep in mind the XK6 is a solid lifter cam, and there is going to be a bit of rattling when cold.

Check the tightness of the eight manifold to downpipe brass nuts. If they aren’t properly snug, you can get a ticking/tapping noise that comes and goes at different engine temperatures.

I’ve never found second guessing engine noises to be very successful. Using a stethoscope or a screwdriver may aid in finding where the noise is loudest.

In my view there are some you can fix without pulling the engine to pieces, and the rest.

So check ancillaries like generator, water pump, distributor, idler pulley if fitted. Check and adjust tappet clearances and tighten the timing chain. Look for loose things and things that are close to things that move, like the crank balancer and the fanbelt.

Once you run out of ideas, if it’s still there it’s inside the engine and there’s only one way forward.

Update, the clackety noise comes from the middle (longitudinally) of the engine, I’ve checked the downpipe brass nuts, all good, it’s definitely not an accessory noise and it sounds like its from the cam cover area. I’ve tightened the upper timing chain and backed of 1 tooth.

So I watched the oil pressure gauge as I started it cold; the needle doesn’t move for about 20 seconds and the engine is nice and quiet, then the needle starts rising and the engine slows slightly (due to the drag of the oil pump) and the whirring/clacking noise starts and continues till it’s warmed up.

So oil pressure seems to cause the noise (seems counter-intuitive). Any opinions?

I think you’re misinterpreting this. In the first post you said the oil pressure was there quickly and 20s is not quick. The engine could slow because it warms up, maybe the mixture changes and it starts to knock or something until it is hot. Maybe your oil drains into the crankcase, but why would this explain knocking between 20s with established pressure after start until hot?

If a lack of lubrication was making it make noise it would be audible instantly…

I believe that in the past someone reported an oil pressure relief valve that chattered when it was opening/closing due to over-pressure on cold start. However, I’d have thought that it would be hard to mistake this as coming from the cam cover area…

Possibly there is some oil remaining on the exhaust valve tappet buckets from the previous run, which is thrown off after 20 seconds, and then the clacking starts on one or more cam lobes.

Possibly the exhaust camshaft oil bore is full of gunk, and it takes awhile for the pump to push through enough oil to get it to the valve tappets. I could believe a so-called competent shop forgetting to clean it out.

But 20 seconds is way too long for the pressure to come up at the gauge. I assume you have the original Bourdon tube mechanical gauge, not some electric conversion?

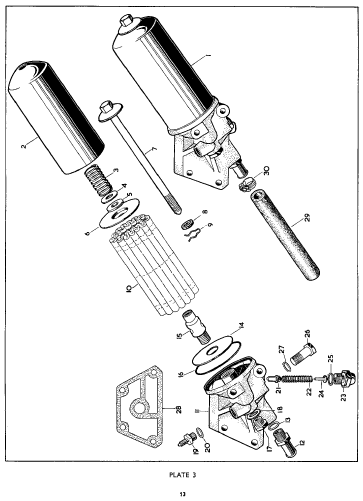

First confirm that you have the correct hollow banjo bolts in the oil feed tube.

Then you may want to look for gunk buildup in the oil filter housing.

time to get a mechanical gauge on it

did have regulator spring clacking once (in a Jag auto trans)…scared the cr@p out of me, sounded like trans was thrashing itself to death for sure, (test drive, was low on initial fluid after I refurbished it)

Your guess is wrong if you believe any noise or slowing is due to oil pump drag kicking in… Noise or no noise, the oil pump moves from the first rev to the last.

If you think it is coming from the exhaust cam area, try cap removal to see if that makes it louder and/or pour some oil in to listen if it goes quiet. Does it have the original cam feed from left rear, or a later XJ spin-on filter housing with feed to the inlet cam first? Is there a crease in the crossover feed pipe, which can easily occur by contact with bodywork during installation? I agree with suggestion to plumb a master gauge into the main gallery.

If it’s idling slowly it may be the transmission knocking, or a lower timing chain, both go away as the engine warms up, and speeds up, and neither is harmful.

So, I can give the final report on what the cold startup noise was all about. Over this past few months I pulled the 3.8L engine out of my XK150 put it on a stand and proceeded to dismantle it. I found piston and bore wear on the thrust side; with one cylinder notably worse. When I ran a bore gauge in the cylinder it showed 3 to 4 thou ovality/taper. The pistons were already 40 thou over so I bit the bullet and hauled the bare block to my machine shop and had them put new liners in, bore & hone to match my new set of standard Hepolite pistons and skim the head surface (incl timing chain cover); in the meantime I removed valves, checked the guides were ok, lapped them and cleane

d/painted everything. I just got it all back together again and it doesn’t make that piston slap noise any longer, so I’m very pleased, just have to get some more break-in miles on her.