I can hardly believe it either, as I have never heard of them failing,

but after listening closely to the hiss emanating from the rear carbs compared to front one, there is something not right to make the air distinctly turbulent, as opposed to loudness of hiss.

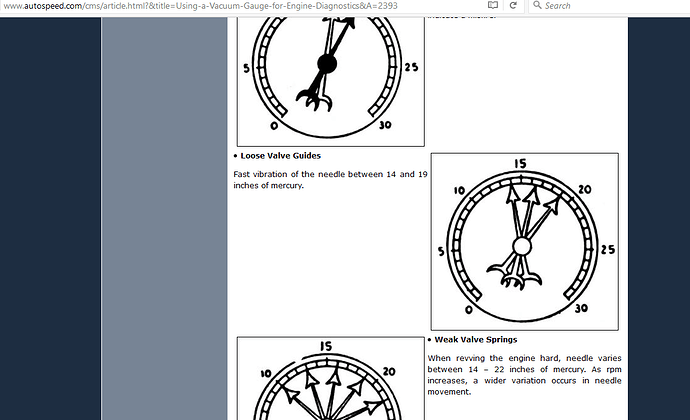

imo whatever this is, that is causing the vacuum gauge needle to flutter

I followed the correct procedure for Carb setting from the FSM (again), tried a few things, to no avail.

The idle is not smooth enough, and even though it drives a lot better than with the previous motor, i can feel there is some imbalance

they are HS8, fitted with correct needles for this engine, and manual choke.

the variation of adjustment is quite small, the air idle screw on the rear one is different, (much longer), that was misleading me a little…someone has been in there before me

I think difficulty balancing carbs could be due to different airflow back vs front possibly caused by unequal air draw from cylinders, one or more

the HS8 throttle plates each have spring loaded contraptions, which on other HS carbs I have seen brazed up, I suppose it is possible there is some issue there, so I will remove and check them.

- edit I have 2 pair of HS8 spare, may change out the rear carb to eliminate any possible problem there

currently searching for my IR thermo gun to check ex manifold temps, which would be a good clue

(exhaust mixes in front resonator so dual tailpipes dont help much)

like it says in the FSM, valve clearance and other timing issues must be attended before tuning can be done, I can only work thru the issue systematically.

I showed the vehicle to an experienced mechanic and discussed it with an expert.

The first guy was clueless, but he agrees idle is not good enough, expert guy said just drive it till it manifests.

the valve springs I would only do as a last resort, prior to remove head, if all else fails.

the vacuum chart that most closely matches mine is “worn or loose valve guide/s”