Is there a central lubrication system in the Mark IV ( such as in e.g. RR) or nipples only?

No, never supplied with a lub. system or remote nipples. You just have to crawl underneath and attack them individually.

Peter

And there are a lot of grease & lube points. My own opinion and experience is that if you use modern molybdenum greases and nano lubricants on new parts during a restoration, the need for periodic greasing is much reduced.

Yes, I think you are right. I have always used graphite grease or moly grease. It does get displaced though. The hassle of replacing king pins or worse still of rebushing front axle eyes makes me service the king pin top and bottom nipples fairly regularly if nothing else.

Peter

@Peter_Scott

Thank you for your prompt reply.

So I will go for graphite or moly grease and repeat it anyhow.

Damn that takes me back to bushing my Morris 8.

Hi Robin,

I didn’t mind the king pins so much as the axle bushes. Fortunately I was much aided by Denis Foxley of this forum. Denis told me of a guy in London who used to rebush London buses and had a very good reputation. This was excellent and Denis even met me off the plane from Edinburgh and transported me with my axle to the rebusher. This was more than 20 years ago and just a few days before my trip the security services had shot dead a guy who looked suspicious because he was carrying a wooden table leg wrapped in plastic in London. I had also wrapped my beam axle and took it on the aircraft as hold luggage. Being rather heavier than a table leg I was slightly concerned that I might suffer a similar fate for carrying a heavy weapon! Fortunately nobody challenged me on that trip or a few weeks later when I returned to Edinburgh with it and Denis’s recommendation has proved to be a very good one for which I am eternally grateful.

Peter

Yes, the modern oils and greases are a universe of technological advancement ahead of the ones in the era of these vehicles. Lubricants had poor ‘sticking’ power and poor resistance to high loads, high speed and high temperatures. It was not unusual for engines to need a rebore and regrind at 50,000 miles or so. King pin grease would easily work its way out or dry out and just leave metal-to-metal contact. The same with UJs. The onerous factory lubrication schedule can be stretched quite a bit nowadays and does not need that frequency of attention.

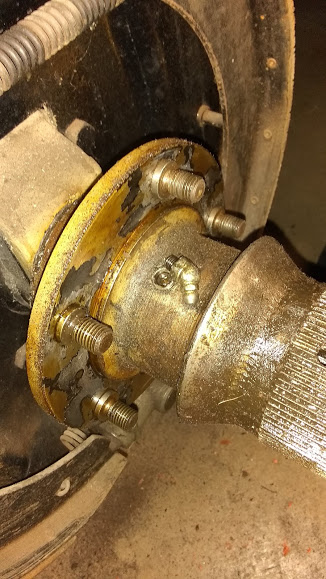

One other special note is the grease nipples on the front hubs and the rear axle bearings. And the water pump. Simply ignore them.

The rear bearings need only be done for the initial setting up. The reason being that the axle oil finds its way to the bearings randomly under driving conditions like a modern car. Also, it is easy to oversupply the grease which can be forced past the seal and into the brakes and axle tube. You can’t feel a resistance to the pumping and you have no sense of how much is going in or where.

For the front hubs, the principle for the greasing was to force the old grease through the bearings to supply the running surfaces with fresh grease. For this to work, the complete cavity between the bearings must be full. That’s a lot of grease, nearly all of which will never be used. Additionally, the spent grease passes the inner seal and the outer adjusting nut. It goes through the discharge opening at the back of the brake plate and onto the garage floor or stays internally and migrates to the brakes; and the outer emission finds its way past the wheel spinner and/or onto the spokes. All this ugliness was normal for the times and helped us old car nuts by protecting the undersides of the car with crusty oil and grease.

There is no resistance to pumping the water pump also and you can easily get grease into the coolant.

So, don’t overdo it and treat these the same as a modern car - that is, don’t grease them. Make sure they are set up with an appropriate high pressure/high temperature grease and then you can pretty much leave them alone. For the front hubs, just grease the bearings liberally but don’t fill the void. Filling the void has another disadvantage - it is then a big insulator to hold the heat from heavy braking.

King pins are such a close fit that grease may not go past the bushes and will short circuit. Should a heavy EP oil be used?

All learned over decades of working on getting the cheapest cars I could afford back on the road. All open discussion points here.

Peter.

I very much agree with Peter’s thoughts above. Regarding the king pin greasing I don’t find that the nipples make a good connection to my grease gun but fortunately I can unscrew the tip of my ancient gun and reveal the male thread that is the same as the female thread when I remove the nipples. So with the gun firmly attached all the grease goes into the bushes without escaping.

Peter

I want to disagree on one point, the front hubs. I have been taught that you should fill the void between the bearings, because hot bearings is your enemy, and the grease draws heat away from the bearings. This is the reason that disc wheel Jaguars such as Mark V have a grease fitting in the hub.

edit: I forgot that wire wheel hubs have them too.