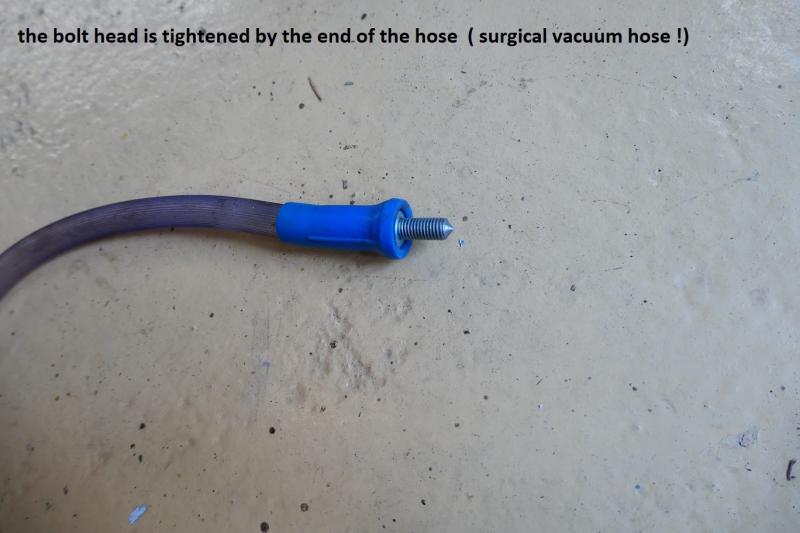

Along the restoration it happens sometimes something unexpected…I couldn’t bolt a bumper bracket on the chassis . One of the bolt has no acces for a socket, even for putting it i its location.

My old brain was heating to find a solution:

you will find the nut was originally welded inside during manufacture of chassis

I can’t quite make out which bolt this is - is this caused by an absence of a captive nut? Or are you saying you couldn’t get the bolt into position to engage with the captive nut, which was still present? I didn’t have this problem with my 140DHC, the bumper bars just bolted right on the outside of the chassis. I’ll have a look today to remind myself.

There was not any captive nut inside… that was the challenge ! ![]()

I still can’t see why you are threading wires into the suspension turret. The bumper fixings on a 140 are all well forward of that. In this photo, the rearmost mounting bolt is the one in the middle of the picture, well in front of the tower. Perhaps the tower is the only way in? You really need a captive in there - I think I’d make the hole bigger, and weld the correct nut into it, finishing off level with the surface. Hold the nut in place with a long screw whilst tacking.

Roger

Hi Roger, the chassis was powder coated “new” and i have not noticed the missing captive nut so i thought it was a good idea to insert a bolt inside the “tower” and doing that i could screw the nut from outside…what i did !

Roger:

From the first photo it looks to me as if “polse”, in using “bumper”, is referring to the rear bolt locating the suspension rebound rubber, or am I completely off base?

Chris.

Chris.

Chris you are right… my english words are not specific enough… sorry for the misunderstanding

PS: the first photo is the final result … bolt in place !

Now you’ve said that Chris, I can see that you’re right - that’s exactly what it is, and I should know - that was the only chassis captive nut on my car that was stripped, so I had to replace it. I did it the way I described, by welding a new nut in the enlarged hole.

Not sure what your native tongue is polse, but I bet I can’t speak it as well as you speak English!

I am French…. Nobody is perfect!![]()

![]()

Envoyé de mon iPhone

I have severe withdrawal symptoms at present, because I usually drive two or three classic tours in France every year and have not been for nearly three years now due to the virus.

I absolutely love France with its wide open, empty (by English standards) roads - even the motorways are scenic and good to drive on! I have three trips planned this year, a Tour de Bretagne in early summer and a Tour des Pyrénées later in the year, with a ‘modern’ drive down to Lac du Bourget in July. We use a classic Mustang for the French trips because the steering wheel’s on the right (left!) side.

I can’t wait! Vive la France (et sa gastronomie…)

If you drive along the atlantic coast… i offer you a good stop in LA ROCHELLE . Excellent oysters and fishes…

Just in case ![]()

NEW problem …!

How can i put the “bakelite” part inside… i tried with a press ( 1.5 ton…) the ext diameter is 44 mm and the diameter of the metal parts is 41 mm ? am i missing something ?

Yves,

This subject was dealt with some time ago. In the old systems you will find a steel ring in one of the half spheres. The old “bakelite” part (it was made from a very hard wearing pressed fiber named Morganite) was shorter but the modern replacements have this shape. Here you see the two types.

Try to get the steel ring out from the other half.

Bob K.

Hi…i assume you are Yves…weve chatted on the UK E type forum in the past…i had this same problem recently. …the 44mm cups you have are not for 140/150…they are from E type etc that have a larger ball…the correct ones are 41mm…and fit the smaller ball pin on the 140/150…what size ball do you have…however as Bob mentiones above note the ring depending on what 41mm cup you fit…Steve

It looks to me like his spigot ring is already out.

I suspect a wrong nylon cup part.

Yes i have taken out the spigot , and the cup is 44 mm . The dimension of the metal “cup” is 41 mm .

I didn’t know there was 2 different sizes for the ball pin . I’ll ask the company who sold me the kit and let you know…!

BTW For Steve i am on the Etype UK forum since many years now during the restoration of my E .

This is the lower metal cup housing for the larger 44mm cup and larger ball pin…very different shape to the 140/150 houseing…Steve

The ball is 34.4 mm diameter. But the packaging of the kit is for XK 140 150 so may be an error ?

Steve i recognize in your photo the parts for the E type. and what is the ball diameter of the ball you show ?

Hi Yves…the ball shown above is approx 38mm…the 140/150 is approx 34mm…Steve