The moss travel is 1mm less than the Smiths, but the shutter starts 1mm higher. It should fit and work just as well as the original. And since the stops are easily modified, a little bit of extra lift can be added if the port isn’t fully closed.

I agree Michael…can’t wait to obtain and test, …but it certainly seems that the Moss will work.

Nick

I also agree, I have a spare 434-156 thermostat, the top of its sleeve (cold) will sit .70 inches below the thermostat mounting surface on this 140 manifold.

The bypass slot in this particular ‘140 manifold extends from .30” to .60” below the thermostat mounting surface, so the top of the ( cold) sleeve sits .10” below the slot opening.

When heated, the sleeve can only rise upward by .30” until it contacts the stops, leaving .10” of slot uncovered by the sleeve.

I figure, if I file slightly more than .10” off of the stops, the warm sleeve should be able to rise enough to completely cover the slot.

ahh cool…,(pun)…one of the tests we wanted to see…hope someone can do same on 120 housing…, wonder IF…the file off adjustment to the stop would cause the sleeve internals to move with or without internal unseen damage to the delicate expansion method parts…that could…cause failure? Hope OK…we all benefit if the Moss thermostat will work in the XKs. IF…the sleeve on this Moss has 1+mm more height to it than the Smiths…I was hoping that would off set its 1+mm lesser rise, Since Jaguar factory fitment used the exact same Smiths for the 120, 140, 150,…(other than temp spec)…it should be that what fits one.,…fits all, (assuming that the factory original Smiths fit all …closing the bypass completely as it opened to radiator) No idea if the Triumphs and Healy, MG that the Moss is expressly made for…have similar bypass location measurements as the XKs, Michael raised the point that the car manufacturers knew they had a thermostat manufacture of a certain size/dimensions so all/most “should have” designed their therm housings to use what was being made, but did they,Thanks for testing.,.

below, your measurements with mm inserted, for comparison to other known specs in the 120 housing,

the top of its sleeve (cold) will sit .70 inches ( 17.78mm below the thermostat mounting surface on this 140 manifold.

The bypass slot in this ‘140 manifold extends from .30” (7.62mm) to .60” ( 15.24) mm so is .30 in (7.62mm) is slot width, below the thermostat mounting surface,

so the top of the ( cold) sleeve sits .10” ( 2.50mm below the slot opening.

When full open, the sleeve rises upward by .30” ( 7.62mm )until it contacts the stops, leaving .10” (2.54 mm of slot uncovered by the sleeve.

If I file slightly more than .10”( 2.54) off of the stops, the sleeve should be able to rise that much further, for a total rise of 0.4 in (10.16mm) , enough to completely cover the slot.

and…For the XK120: XK120:The bypass on the 120 housing is 10mm round, and is located within the housing, at its top 5/16 (.3215”, 8mm) below the housing flat surface, so with a diameter of 10mm it is at the low point 18mm below the flat mount. We can say the hole is from 8mm top, to 18mm low and this is what the sleeve has to cover.

I measured all the static dimensions of the Smiths 85025/80, and the Remax NT100/68 **eye-**Dennnntiical (identical), and will soon do same with a few others: …goal is.to find if all are the same in fitment, sleeve, stops, every exterior dimension. . Next…the hot water pot: to find, though spec temps may vary, do they all open with the same travel of the bellows, do they stop before or at the “stops” , what is the open distance, poppet to body, and sleeve to the flange which is the important measurement: to see if the sleeve covers/blocks off the bypass. Since I have a 120 housing, I can test the entire assembly in hot water and visually see if the bypass port is closed, So far, in the two types tested, yes it is, I do expect to find some differences due to the 60 year age ( of parts…not me.,.) so back to cook-up some thermostats on the stove.,Stay tuned. Nick

and now have measured the AC TF1: I also have in front of me, the AC TF-1. It is marked 72C on top of the flange, with AC manufacture code 2235, “AC Made in England” on the base. The later blue box/white horiz stripe (some have yellow) has AC Delco Davison of general Motors Ltd. Dunstable England. The dimensions closely match the Smiths: flange 54mm, 48.3 sleeve diam, sleeve height 16mm, the stop is apprx 9 mm below the inside of the flange, the Smiths a mm or 2 less. However, On the AC there is a 2mm greater distance inside the sleeve, from sleeve edge to the bellows top: it is 4mm and it is approx 6mm from sleeve edge to the stop) (it is more dished than the Smiths-Remax) which is what acts upon the stop (if it reaches the stop on full open it is a total of approx 10mm). The AC is much more dished from sleeve edge to the inner bellows top, whereas the Smiths and Remax are not but the stop is itself different so it comes out the same…9.5mm to 10mm of possible opening travel.

I’ve added a page on air venting, which fills an important gap:

https://www.coolcatcorp.com/thermostats/Air%20Bleeds.html

Also, a request for information. “British Thermostat”, aka Teddington, seems to have made automotive thermostats and thermal controls just after the war. The only detailed reference I have for their thermostat business is that they developed an altitude-compensated bellows thermostat for the Merlin engine. For this, I’ve been able to turn up the patents. The inventor was William Martin-Hurst, who went on to head Rover in the 1960’s and is best remembered for securing the design for the Buick aluminum V8. I’m guessing that Teddington was affiliated with the Reynolds group in some way, or were patent licencees. But the corporate histories are very muddy. If you have any direct information on this company, brochures, first hand stories, even photos of their automotive products, I’d be interested.

Hi Mike

Everything I have been able to find about British Thermostat Co. can be found here:

https://www.gracesguide.co.uk/British_Thermostat_Co

Also:

Teddington Controls: https://www.gracesguide.co.uk/Teddington_Controls

Teddington Aircraft Controls: https://www.gracesguide.co.uk/Teddington_Aircraft_Controls

Regards

David

Not only the design, but the entire tooling went to Britain. That engine went on for decades in numerous BL cars, and I have three of the buggers in my backyard “parts department!”

Teddington thermostats are found on SS and Jaguar pushrod engines 1936-51.

The brass thermostat is captured inside the cast iron housing and not easily removable. The price in 1936 was 1 pound 13 shillings 6 pence.

The airplane in the advertisement is a DeHavilland Mosquito. My dad serviced them in the RAF.

I’ve seen the article on Grace’s guide. It doesn’t say much about automotive designs.

That’s a very interesting thermostat. What are the two side fittings attached to? Are they for heater or bypass?

British patent numbers are tough to research, I’m not sure how to find this one. The search engines available from the UK IP office leave a lot to be desired. The aircraft patent was granted in the US, which made it easy to find:

I would have thought that a high-altitude thermostat would have been sequestered by the UK government, and certainly not published through a foreign patent office. It’s unlikely that the thermostat had much application for civilian aircraft of the time. Nor could there have been much cross-Atlantic research: the Vernet wax motor patent had already been public for four years, certainly a more elegant solution to the problem. An example of an easily overlooked technology potentially providing an important strategic advantage. Or perhaps an example of technological inertia, sylphons being the mature technology of the day.

Search the GB patent number here.

https://worldwide.espacenet.com/

From the menu on the left choose Original Document.

Each page is a separate pdf.

GB patent 421455 pg1.pdf (105.1 KB)

GB patent 421455 pg2.pdf (114.0 KB)

GB patent 421455 pg3.pdf (22.5 KB)

The threaded fitting is for the temperature gauge sensor bulb, and the unthreaded port is the bypass hose connection.

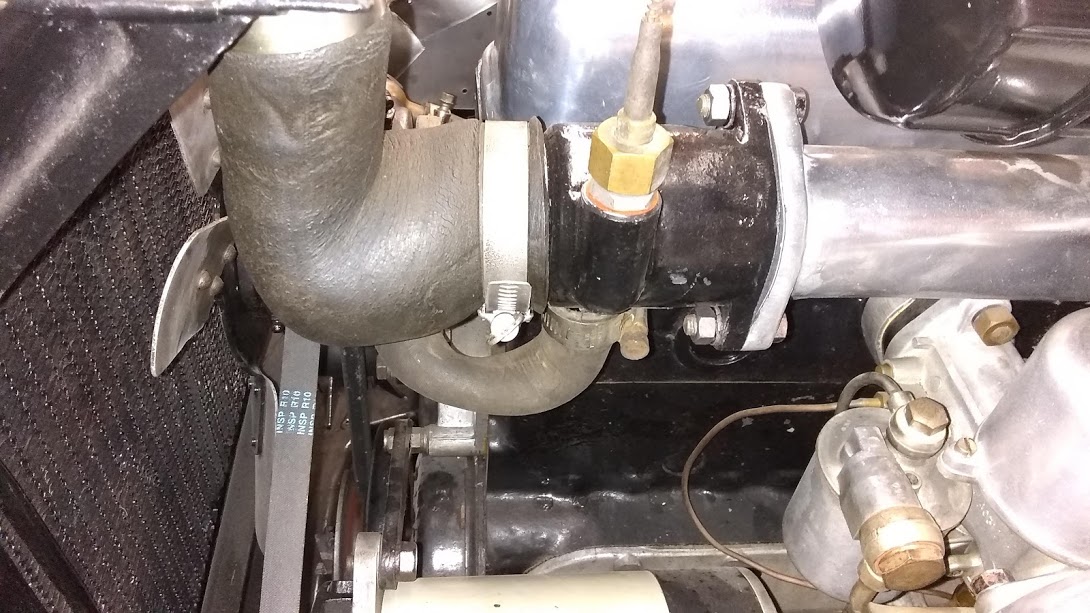

Here is the one in my 1938 SS Jaguar 2-1/2 Litre Saloon.

Here is the one in my 1950 Mark V 3-1/2 Liter Saloon.

I found the '38 SS has been running around for several decades with no thermostat at all, removed by some previous owner. Here is the inside showing the bypass port.

I haven’t read the entire thread, so perhaps this has already been stated by someone:

Re: plugging the bypass hose and running with either a small (3/8") bypass hole through that plug, or the thermostat - There is one MAJOR downside to that approach on a street car. If you run the engine hard, BEFORE the thermostat is opened, you can (and almost certainly will) get localized boiling in the head, which will cause a pressure spike which can easily pop a core plug, or hose. Reducing the bypass is a fine thing to do on a race car which will never be run hard until fully warmed up. In fact, this is exactly the setup Jag recommended for racing. But for a street car, it’s a terrible idea, and has little or no benefit to offset the risk.

Regards,

Ray L.

Faboulous research, thanks Rob. Is it ok if I use some of this? I think this system deserves some attention.

The bypass design is quite advanced for the time. The top of the bellows acts as a second poppet to close the bypass port. It’s similar in some respects to a modern dual poppet system. But orienting the bypass port directly into the flow and piercing the port to allow for the control rod must have made for some serious bypass leakage. Very, very cool.

The XK120-150, Mk 7 Service Manual. p D12, British Thermostat is listed as the thermostat for Mark 7, (early) with a note that it has a domed valve housing, and is retained in its housing by a set screw.

The below from Bob Knijnenburg : See web:

http://www.bobine.nl/jaguar/02-engine/thermostats-for-jaguar-xk-120-140-and-150/

“The “British Thermostat” version was only fitted to Mark VII engines (numbers A2001 to A6000) and this thermostat is non-interchangeable with the Smiths version. The British Thermostat Company manufacured all sorts of thermal control equipment, mainly based on the use of seamless metallic bellows. From 1934 onwards they also manufactured car thermostats in their factories at Windmill Road, Sunbury-on-Thames, Middlesex. Brtish Thermostats was the largest manufacturer of seamless metallic bellows in Europe and must have supplied many other manufacturers of these bellows type of thermostats.

British Thermostat Co. was large supplier of bellows Bellows on a (non-screen) thermostat”

The British Thermostat for the Mk 7 is not to used in an XK.

Also FYI, the Service manual p D7 has “radiator flow figures” by psi. , 22 gallons per minute at 1psi, with a max of 3.5psi for the XK120 49.5 gallons per minute. I have no knowledge of what this info means in practice. ??

Nick (another interesting thermostat web discussion: http://www.mgcarz.com/thermostats.html

Ok with me. I didn’t think it would have much interest on the E-Type forum, but did a little more checking and find the Teddington thermostat was also used on 1934-37 SS side valve engines, attached vertically directly onto the top of the cylinder head.

Ray:

The cross section of a 3/8" hole is .110 sq in. I had to run down to the shop to double check my measurements:

I calculate the bypass cross section of a 3.8 manifold based on a 1.968" cylinder, .1" high, giving a .618" lateral surface area. Since only about 60 degrees of the radius can flow (the rest is dead metal), effective bypass cross section is only about .103 sq in. So a 3/8" hole through the thermostat should just about replicate a fully open bypass. You won’t hear me defending Jaguar’s cooling engineering, but that’s how they did it.

By contrast, the S2 bypass is 5/8" diameter, giving triple the cross section. That’s more bypass flow, but still unbalanced, as the thermostat opens about 1".

Racing experience has no bearing…Jaguar ran a restrictor instead of a thermostat, and still left a partially open bypass. You’d never

Thanks Rob. I’m going to add a bullet to the bypass discussion.

I also fabbed up a 3/8" restrictor button, to go in the bypass hose, and ran Tweets many thousands of miles, no issue.

Mine is smaller than yours, only .34".

Just put the finishing touches in the Bypass Systems page. I incorporated the history page, so it’s a bit redundant at the start, but there’s good stuff if you get into it.

https://www.coolcatcorp.com/thermostats/Bypass%20Systems.html

Excellent work Mike!