The archives seem to suggest that 3.8 and 4.2 camshafts are the same between series 1 e-types. What about between Mk10 and e-type in the pre-'68 era? Can’t seem to find anything on that, but I suspect the cam profiles for the straight port heads were the same in the saloons as in the e-types.

Are the part numbers stamped on the cams the same? That would be the easiest way to tell.

They are all the same basic part number with different suffixes, the latter far separated in the stamping of the 1st two cam sets. I have loose cams from a 3.8 Mk10 (MC20889 K and MC20889 J)and a 420G (MC20889 -2 and MC20889 -7), and I have a loose head from a 3.8 e-type (MC20889-1 and MC20889-G if they are original to the head - not sure), but I thought that it might be common knowledge what profiles Jaguar used, i.e. whether they were different between e-types and saloons.

I’m in the process of putting together a missing cylinder head for a 3.8 e-type and was planning to use the Mk10 cams. I’m gathering from your note than none of these may be early cams, but that is a bit confusing, as I would not have guessed these Mk10 cams to be unoriginal. When did they start with the MC label?

My parts book lists the 3.8e as C17138 and C13081. The Mk4.2 parts book lists C14985 and C13081. I can measure that lobe height today. I don’t see cam lift in the manual. Do you know what the e-type is supposed to be?

The MC 20889-X is just a casting number. There is a hand stamped number that identifies the specific engine type it was originally installed in.

…the timing cam profiles are well know…duration , we know the lift on most. We know the Jaguar part numbers.(tho Faint and often hard to find at all) .and to what engine they would have been in. What is not found…is the dimension of the various cam lobes…heel to tip on a new cam…of each cam Cxxxx part number: …we know the lift…but not what the total dimension should be new…thus how to measure it and compare to new spec. May as well determine the new cam spec for the bearing journals. Let’s say you find nice shiny used cams on ebay…how will you know if the cam lobes are worn? Nick

Aha. That makes sense - I should have know to look for that.

So the cams are C14985 and C13081 for the presumed 420G

C14985 and C13081 for the 3.8 Mk10

C5717 and C5718 for the presumed 3.8 e-type

So, it seems that finding the parts numbers answers the question about using the Mk10 and 420G cam, as they are the same intake cam part number for the early e type up to engine R1217 and the same exhaust cam. It does raise the issue of what the cams are that were sold to me with that e-head many years ago. A quick web-search for the parts numbers suggests that they are xk120 cams. go figure.

It does make my current job a little easier, as I can use the cam that still has the tach generator drive attached, since my machine shop lost the other one. BTW, I am desperate for a quality machine shop in the Pacific Northwest (driving distance from Olympia) should anyone have a recommendation. The work that I just got from a local shop is a joke.

3.8 Series 1 E-Type

4.2 Series 2 E-Type

3.8 Mark 10

4.2 Mark 10

3.4 S-Type

3.8 S-Type

420

3.8 Mark IX

3.4 Mark 2

3.4 Mark 1

3.4 Mark VIII

3.4 Mark VII

XK150

XK150S

XK140

![]()

![]()

XK120

2.4 Mark 2 and 240

2.4 Mark 1

XJ6 Inlet

XJ6 Exhaust

Sorry I don’t have Daimler DS420 and Alvis Ferret.

Thanks all - very helpful info.

still tryin for measurements…XK120-140 150 cams, heel to lobe tip…the timing cam profiles/duration are well know…, we know the lift. We know the Jaguar part numbers.(tho Faint and often hard to find) .and to what engine they would have been in. What is NOT found…is the dimension heel to lobe tip of the various cam lobes…( May as well also survey/determine the new cam spec for the bearing journals). Let’s say you find nice shiny used cams on ebay…how will you know if the cam lobes are worn? Nick

I can measure those used 120 cams if that is helpful to you. As you point out, you won’t know what the new measurement would be.

Point the lobe straight up. Mic it in the vertical plane, heel to nose, then in the horizontal plane, flank to flank. Subtract the second measurement from the first. In an unworn cam, the result should be the published lift.

hmmmnnn…that may be so…but…it could…not necessarily be so…the lobe could be…whatever…on the circular base…couldn’t it? Have enough C5717 C5718 cams been measured this way to know that that is the case…and…I’d still like to know…distance from lobe to the cam heel on opposite side…seems easy enough with a simpler caliper. One measurement…no math to do. Nick

Hi, at my advice all the camshafts are the same.

E type, XJ, all…

except the early with XK 120 and MK1 . Low (little) lift , so : less horse power.

and except the last camshafts from XJ S3.

Betwen us this camshafts are poorly developed. E 4.2L : 230 cv DIN : 53 cv/litre only !!

So far as I know, the distance from the heel of the standard cam to the cylinder head is the same for all XK heads, therefore the base circle has to be the same. For these flat tappet cams, the flanks are the same as the base circle.

For an all-around, flexible street engine, that’s really not that bad.

now I am really in a fog…what is meant by heel to cyl head? in situ the heel is above the follower (tappet or bucket). and distance is the clearance…which depends on valve stem/shim/tappet. …and I don’t understand the “therefore”…??? any way… what is…the as new distance from lobe to the cam heel on opposite side…for a 5/16 lift cam, and for a 3/8 lift cam.? still tryin…

Nick

From the factory service manual, the standard clearance from the valve tip to the heel of the cam is 0.320".

“The figure of 0.320” includes an allowance for an adjusting pad thickness of 0.095" to 0.097" which will, if necessary, permit the fitting of thicker or thinner adjusting pads…"

ok…that is an interesting spec IF the cams are removed…and IF the vale stem has not been altered, if that can even be determined in situ, and it is a bit difficult to measure as the valve stem tip is in a recess. Still does not tell me how to evaluate a cam lobe with one measurment…heel to lobe tip…searching and seeking that spec…tho it may be the cross section of the circle…plus what is supposed to be the lift. ?? Nick

To evaluate a cam lobe you need two measurements.

A minus B equals lift.

B should be pretty much constant for all cams.

The lifting part of the lobe never extends around that far.

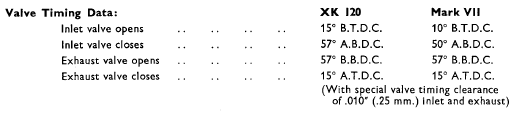

These figures are crankshaft rotation. Camshaft rotation is half these.

So the lifting part of the camshaft is 7.5 + 90 + 28.5 = 126 degrees.

120 degrees for the Mark VII inlet.

But they don’t normally get worn around B where they don’t touch the tappet.

Unless they have been worn or reground. I believe I had one that was badly reground, for which I provided measurements for this discussion.

I believe Mike’s point was that C (head face to valve stem) is constant within tolerances for all XK engines, and tappets are made to tight tolerances, so for valve clearance you use various thickness adjusting pads. There are depth gauges made for taking this kind of measurement.

Undoubtedly the factor assemblers would have used this tool to know the right pad to install.

Unless the valve stem has been damaged or ground, or the valve seat is receding or something. Then you may be out of the available range of pads, too thick or too thin.