I hope I’m in the right place for this but it’s my first post so please be kind. About 18 years ago I first got my hands on an XK engine in a Challenger Mk1 E type replica and immediately felt for 4.2 litres it could probably do better so after a few miles and an engine rebuild I looked into it in greater depth. As you all probably know the original design was not 4.2 and when good old BL decided to move the liners apart to make room for it to be 4.2 they never bothered to design a new cylinder head, consequently not all the combustion chambers are over the middle if the pistons and the 3.8 is generally considered more enjoyable to drive as a result. Being an electronics engineer it seemed to me the best way to fix this was with an engine management system capable of trimming the cylinder fuelling and ignition timing individually, ie put the system back into balance electronically. I looked at the xj6 efi system and was astonished how badly designed it was so I had to set about designing my own which was built from bits of tubing etc from other FI manifolds found in the scrap yard tig welded to the stub of a jaguar unit with all the runners sawn off so I could still get water in and out of the engine in the normal way. The project progressed quite well using a trigger wheel from a Daewoo in the scrap yard machined to fit the front of the crank though I had to go to an electric water pump as there wasn’t room for the water pump pulley. At the time the only suitable ecu I could find was an Electromotive Tec3R using 3 double ended coils like the more modern Megajolt favoured here uses. I established some basic maps and swapped the E type gearbox for one less likely to be broken by the extra torque (Supra turbo box) and it ran ok.

The next step would have been rolling road mapping and cylinder tweeks but at that point I had a major domestic upset which resulted in a house sale and losing half my assets etc. It’s taken me a while to get back on my feet setting up another house / workshop living alone but now I’m trying to pick up where I left off and I see things have moved on a bit in Jaguar land. Sooo, after all that preamble what I’m asking here is do any of you have any good basic ignition and fuelling maps / tips and tricks I might be able to learn from during lock down before I go to rolling road tuning. Has anybody else messed with cylinder trims or knows anybody who has?

Welcome to the forum Rod.

I know of many ECU swaps for the V12 but not for the XK, so I can’t help you with the specifics, but just to say that it sounds like a very interesting project and it would be fun to see more of it!

Best of luck,

Aristides

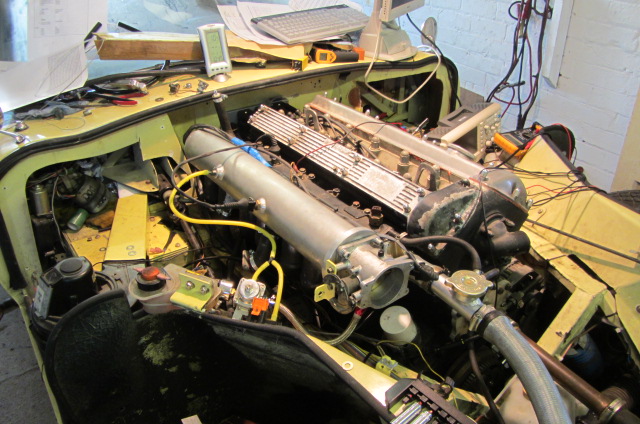

Aristides: There is so much you could do with that V12 once you remove all the BL strangulating stuff but I’m not sure I’m brave enough to tackle one of those. Anyway I’ll try to post some pictures of the XK thing, only second post so I hope it works!This was before I started enginefront|375x500

This was the Supra gearbox fitted

The plenum before the end was welded on, the tube is from a central heating boiler flue pipe, note the extended runners and bell mouths for extra torque.

First fit to the engine.

I had to bore out the lucas injector mounting holes to take modern bosch injectors, the ones I used should be good for up to 500 bhp if I decide to add a turbo or two later.

I’m trying to figure out what kind of XKE scuttle panel that is…?

This is super interesting to me as I had converting my car to EDIS, but want to do something like this one day. I haven’t found anything I liked off the shelf or from existing jag parts, everything seems to have significant downsides or won’t fit in my Mk2. And I don’t want to spend the $ for Jenveys.

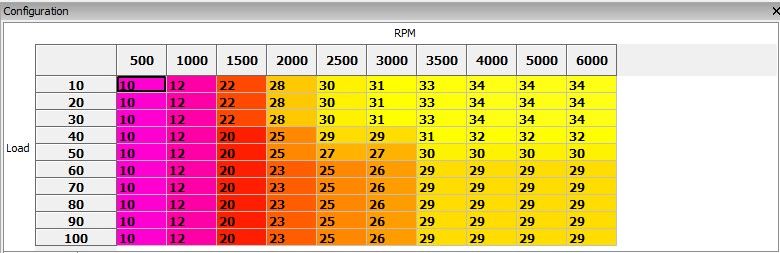

Here’s the EDIS timing map I started from, had to tweak it a bit to solve some pinging issues but it’s basically mapped against the S1 4.2 E-type distributor. This is total timing based on MAP load.

Thanks Theo, unfortunately your EDIS map image isn’t displaying on my browser. Curiously, the first picture I dragged into this thread appeared as a link even though I did exactly the same as I did with the others. If you want to experiment with your MK2 FI without damaging the existing carb setup, try to get hold of an old series 3 xj6 injection manifold as a base, once you’ve cut off the runners it’s not difficult to make modern injectors fit, then you can attach anything you like to that and easily revert to the carbs at any time. The fuel rail is the only thing you will need to spend money on. I tried various options to make my own but struggled to make it seal properly. There was a guy on ebay offering to make custom rails from aluminium if you sent him a drawing, it wasn’t too expensive. You don’t have to have the ideal runner length or the perfect plenum to make something which works better than the old carbs. After all, even the Lucas xj6 setup where everything about it is wrong (the worst bit being where the air inlet blows directly into ports at one end) still manages to work after a fashion.

it’s ok, I’ve found I can open the map as an attachment to the notification mail.

Paul I think it must be the Challenger Mk1 E type replica that he mentioned in his first post.

Thanks! I clearly missed that!

Hello Rod and welcome. If you use genuine trim and lights etc a good Challenger will fool a lot of people and is the ideal car to experiment with EFI.

It was Jaguar who shuffled four of the six bore centres, not BL. It made no difference to running and there is no practical way to ‘compensate’ for it by mapping engine management.

There are people like Dave Rose on the E-Type UK forum who have done similar conversions. Marek Hermaszewski is very au fait with EFI & EDIS.

The Supra box is OK but it only fits your SWB because it has a very different tunnel compared to any factory body shell. The fifth gear will be nice but the standard 4-synchro was never ‘likely to be broken’ by your changes. It can handle any torque a Jag XK or V12 could send through it.

Hi Peter, thanks for the kind welcome. Of course you are right about it not being BL who made it 4.2, it’s 18 years since I read about all this and some of the historical details have probably got a bit mixed, I was probably thinking about the horrible prince of darkness injection system. You are also right about Challengers, most of the jag engined ones have been finished to a very high spec with as many genuine e-type parts as possible. The guy who made the kits took his own series 1 to pieces to make the moulds for the fibre-glass, the only way to tell at a glance with the bonnet closed is the wider tunnel and a couple of bits of square section tube just visible under the sills near the front. I saw some superb examples when I was editor of the owners club magazine.

However, technical debate is good so I don’t necessarily agree with you over the effect on the running due to the shuffled bores. The usual justification for it making no difference is that the chamber in the head is smaller than the bore diameter - this is fine at TDC but as the burn takes more of the stroke the propagation of the flame is likely to be different if the starting position is offset (IMHO). If this isn’t the case can you think of another reason why most people who have owned both 3.8 and 4.2 cars say the 3.8 is a much more willing and responsive engine, more fun to drive. Also, my old friend the enigmatic and reclusive Jaguar racer EikeWellhausen (who I spent quite a lot of time discussing this idea with) admitted one reason he usually wiped the floor with works teams was his cylinder head which had the chambers all over the piston centres. I don’t really see why any imbalance between cylinders shouldn’t be compensated for by mapping but I’m ready to listen to reasons.

At the back of my mind I did think I might add a lightly boosting turbo or 2 once I got it running well without. It was another old friend Ken Jenkins (who formed JEC and must one of the most experienced Jaguar experts in the World) who persuaded me the Jag gearbox might not last long though he wanted me to use a different box from a race car he had kicking about, I can’t remember what it was, I don’t think it was a Getrag or a T5 but it was a while ago so it might have been. I went for a walk round the scrap yard with a tape measure and decided the supra box would fit (with a new prop shaft). Bought one cheap off ebay, took it to pieces and it seemed well made so I put it in the car. The old 4 speed with O/D brought a very good price an ebay which paid for a lot of the other stuff.

Thanks so much for the names, I’ll search for Dave Rose and Marek Hermaszewski,- today I slightly modified my ignition timing base map using the information from Theo but the weather precludes any road testing at the moment.

I think a good deal of that can be attributed to the much heavier 4.2 flywheel.

It might contribute a little bit to the difference, but I haven’t seen any data yet to convince me the bore spacing versus the combustion chamber position has that great an effect.

There are quite a few people on the UK forum who have modified the 6 cylinder XK powered cars. The answer to your question comes in two parts:- an ignition map and a fueling map.

There are plenty of ignition maps already posted. You want to chose one that matches your camshaft as a racing cam will want to idle differently from a street cam.

The fueling map is something you can usually make up yourself if you have access to a wideband and user configurable software.

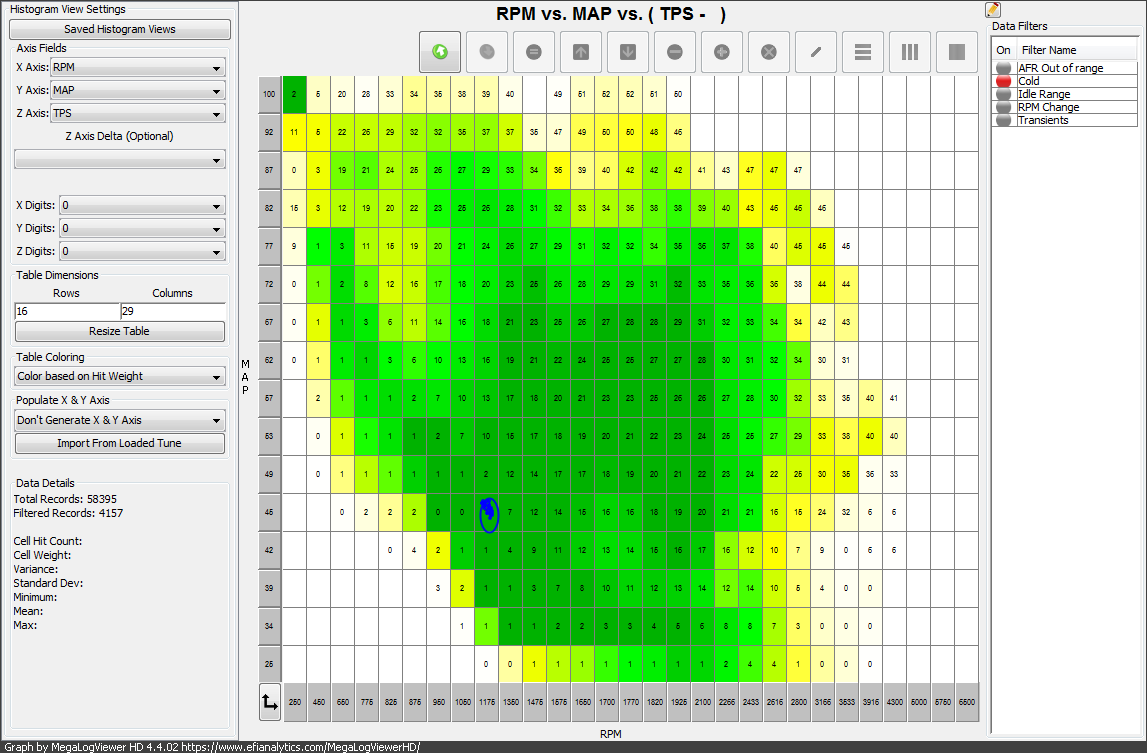

There is a lot of good advice on the msextra.com website which translates over to any car, not just a Megasquirt (“MS”) fitted car. The key to a lot of this is to have datalogging capability, which on a MS car is supplied through the Megalogviewer free software. The paid for Megalogviewer HD version (about USD50-70 iirc) allows you to plot graphs and tables of anything (or any data derived from a formula thereof) to aid your understanding of how the engine is running.

As an example, here’s a graph of how open the throttle is versus the reading taken from a sensor on a ported vacuum tapping on the throttle body during a test drive. The 100% load line shows that WOT is achieved at just 40% opening at 1350rpm, i.e. the engine has all of the air it needs at that speed and opening the throttle any more simply makes the

revs go up.

This graph shows what the air pressure reading is at the ported vacuum port on the same test drive (at sea level). Normal air pressure is 100kPa and 100% vacuum is 0kPa, so when the throttle was shut on the first graph (a reading of 0), then you’d expect it to generate no vacuum as the reading is 100 because the port is on the airbox side of the throttle plate.

This sort of capability gives you the tools to answer “what the engine was doing” and the basic log graph tells you “when”, i.e. cause and effect. That’s how you’d dial out resonances and flutters in your current maps.

Essentially, go for a system that allows you to datalog your engine, if you want to know the reason why it does what it does. Without that, you’'ll always be paying someone else for every mistake they make as they learn rather than you.

kind regards

Marek

We obviously moved in the same circles Rod. I tried practising my German on Eike at Chatsworth Motor Spares when I lived in Chesterfield and have dealt with Ken since he helped at Great Longstone with Derek Watson. Nice guy and very unassuming. I toyed with the idea of a Challenger as a cheap way to get my convertible kicks but found Mustang-engined S2 OTS for the right money and de-lumped that instead.

The 3.8 has a 6lb lighter crank and slightly lighter pistons, which allows the rev limit to be a little higher. The port velocity probably hits the sweet spot a little higher too, due to the smaller swept volume.

Although the standard 3.8 and 4.2 flywheels weigh roughly the same, for the E-type many (most?) 3.8s had a lighter version, which as others have said does allow the motor to feel peppier, even if the 4.2 torque ensures the 3.8 doesn’t pull away.

If you go onto the AJ6 Engineering site you’ll see Roger Bywater near Macclesfield made a big plenum/short runner intake like yours. Think it was for the AJ6 or AJ16 though. Like Eike, Roger can be a bit grumpy with out-and-out time wasters, since they are/were both busy men, but if he’s still in Bollington he might have EFI info for you. Not that you need an excuse to go for a drive over the Snake or Cat & Fiddle passes…

He also did it for the S3 XJ6.

Forced induction or N/A?..

You may well be right but until I try I wont know for certain and it makes a good project, I’ll report back!

NA as far as I remember, we have a guy here based in Rotorua who is building up a 4.2 XK engine with twin turbos that he is putting into a S111

He has designed and built his own exhaust manifolds, waiting for a while until he has it a bit further down the track before I ask for a club run down to view the work.

Thank you so much for that, those graphs are particularly interesting, I’ll print them out and give them a good study over a pint before bed. Were they from an XK engine and if so was it a home brewed plenum? I Chose the Electromotive TEC3r when I started because it seemed to be the best option at the time (if a bit pricey). It does have the option to datalog most things and change things on the fly. I’m sure the data on the MS website is transportable as I don’t want to start wiring a different unit in now if I can help it.

I’ve got a pretty standard series 3 engine/cams - again at the time there were plenty of old XJ6 lumps about so I thought, given the chance of blowing it up during development, (particularly if I add a turbo) it would be cheaper to destroy a standard engine and if something fancy was justified I could do that in the next iteration though I hoped with a bit of boost and good mapping a standard engine might provide enough power without changing cams etc. I’m guessing there is no longer a massive pile of expendible old XJ6 lumps going spare!

I probably need to change to a wide band o2 sensor as when I first put it all together I was keen to get something running to see if it worked at all so I just went to the scrap yard and took a standard on/off sensor which looked clean and easy to fit from a car there, can’t remember what it came off - possibly a Saab as I think that’s where the tickover control valve came from. The weather has not been good enough for any road testing, I couldn’t even get it up and down my lane if I wanted to for snow and Ice so I’ve concentrated on making things like the Tacho work accurately and experimenting with cold start enrichments. Thanks again for the good advice. Rod

Hi Peter, your name sounds familiar, perhaps we met at Eike’s or he mentioned you. He was like Marmite in reverse, he either liked you or he didn’t. I used his lathe to make the Daewoo index ring fit the jag and a couple of other little jobs, for some reason we got on quite well. His long suffering old mechanic (who’s name I’m struggling to remember) rebuilt my LSD for me too. I’ve never seen an E with a mustang engine, did it require much chassis modification? It would be interesting to see a picture. I take your point about the higher port velocity of the 3.8.

I calculated the plenum volume and runner length/diameter using data from a couple of books, Engine Management Systems by Jeff Hartman and “Forced induction performance tuning” by Graham Bell. The runners aren’t that short, that’s one of the reasons I curled them round to get some extra length. The outside of the runner tube is 13 or 14 inches from bell-mouth to the head. I think I remember speaking to Roger at the beginning, where in Bollington is he? I used to keep my canal boat there. These days I live near Chapel so the road to Macclesfield is only 5 minutes away. I’ll look at his web site.

“Forced induction or N/A?” At the moment it does run N/A though not spectacularly well (it managed to drive here ok when I moved house) but I did think the incredibly compact turbos they fit to Mitsbishi Delica 2.5 diesels might just fit in the space available…