Warning: Sit down - long post!

Wow. It’s hard to believe two months have gone by since my last update!! It feels like I’ve made a lot of progress but when I stop and reflect, it doesn’t seem as significant as it felt. After I got the engine running I uncovered some other issues that needed to be resolved. Note that I have been able to diagnose and figure many of these things out through the great sources of information on this forum - I have barely used any of my manuals at all (yet). I thank you all for that!!

First off, the 3-wire 10SI alternator that was installed was overcharging the system - at one point I’d measured 16.4v at the battery, and 15.5v at the ignition coil. I disassembled the 10SI, and while I could have rebuilt it, I chose to install a 3-wire 12SI for better cooling, easier workload on me, and not much more money (if any at all). I didn’t really need the 12SI higher amperage output (78 amps), but I sized the wiring to accommodate it.

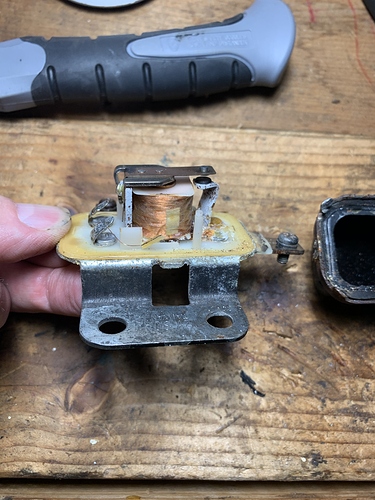

As as example of the 10SI internal condition, here’s the diode trio I removed!

Here’s the 12SI installed:

While I was at it, I also removed/replaced some “extra” wiring that was no longer needed, and removed the generic ammeter so I can install my new voltmeter (maybe this weekend). It took me a while to trace all the wires connected to the aftermarket ignition “relay” that was installed in the stock location near the battery, and to also figure out how it was “supposed” to work. It turns out that the “relay” function was not working (bad internal ground connection) and it was mainly functioning as a terminal junction block. Figuring all of that out took me quite a while with my multimeter.

Wiring I removed:

Ignition “relay” external

Ignition “relay” internal

Generic ammeter, and new Smiths voltmeter

I also concluded that the wrong ignition coil was installed. It was measuring 1.6 ohms and considering that I don’t have a ballast resistor, it should have been 3 ohms. Combine that with the over-voltage from the bad alternator, I was really pushing some current through the coil!! I am surprised the Allison XR700 (installed in 1987) is still alive!! I installed a Petronix FlameThrower 3-ohm coil, new NGK BP6ES/7333 spark plugs, Magnecor 7mm ignition wires, rotor, and a new push-on style distributor cap. I also removed and cleaned all the fuse blocks behind the dash, and reinstalled with all new fuses and a little dielectric grease.

After all of this, I synced the carbs with my new EMPI carb sync tool. I’m not sure if the reading at idle means anything, but with the carbs synced and the engine idling at 750-ish RPM, the gauge was reading ~11.5 kg/hr for each carb. I had ZERO luck tuning the single carb throttle bypass valve (even though I rebuilt it), so i just screwed it completely closed for now.

I completed flushing the coolant system with several cycles of Blue Devil radiator flush and clean water, and luckily the internals seemed fairly clean. The system is now topped off with 50-50 coolant and distilled water.

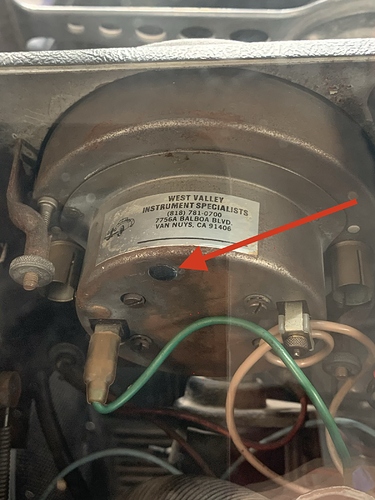

I’d noticed my tachometer was reading high as compared to my multimeter inductive- pickup RPM reading, so I removed the tach to access the calibration adjustment. Using info from the archives, I drilled a hole in the rear housing to allow me to adjust the tach with it installed in the car. It’s now accurate at idle and “close enough” up to 2500 rpm or so. I’ll verify things again once I get the car on the road, which is still quite some time away.

Calibration hole, drilled and plugged in the rear housing of the tachometer:

Next up - brakes. I have ZERO brakes, and I can tell this job is going to take some work. First step I took was to remove the two brake reservoirs, which I did yesterday evening. Neither are in great shape, but amazingly the switches still work! Here’s a picture of the worse of the two:

Sorry for the lengthy post, but thanks for reading, and THANK YOU for all the informative posts that keep me moving forward!!

RobY