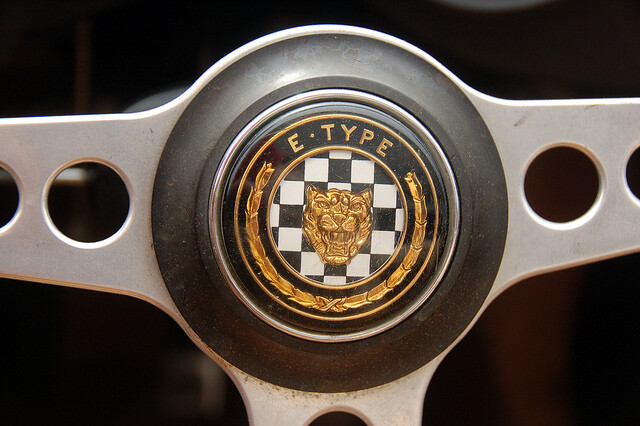

I’ve been driving my '66 FHC quite a bit since it’s recent engine rebuild and have been working my way through a variety of squawks on the car and have it pretty well sorted now, except for two electrical items. The horn doesn’t work, and the dash indicators for the turn signals don’t light up. After almost getting run off the road by a large truck that apparently didn’t see me as he merged into my lane, I decided to dig right into the horn. After solving the horn button removal mystery (three set screws behind wheel), I found that I do have power, and a functioning solenoid and horn. If I ground the center nipple to the wheel the horn sounds, but I think I must be missing a component. The nipple on the end of the center rod rests in a foam, non-conductive seat inside the back of the horn button. I don’t understand how power from the rod in the center of the steering column can get through to ground via the metal ring that contacts the inside of the wheel when the horn button is pushed. I’ve looked at the steering column diagrams and the available horn contact repair kits but still don’t understand how this works. Any help is greatly appreciated.

Hey John:

That’s a horn button for a Series II not a Series I - the black ring between the actual button and the bakelite base is a tell tale sign - on a Series I that ring is chrome. Much more importantly the Series I button has a metal inside contact for the rod - not foam. On the Series II cars the horn is activated by the turn signal stalk not the horn button.

I’m not sure what lies under the foam - maybe it’s metal??? Others, much more knowledgeable on the subject will likely chime in to guide you through this. Good luck getting this sorted out. ![]()

Ah Haa!!

Yes, I replaced the steering wheel with one I sourced off ebay as the wood on mine was cracked. I didn’t realize it was from a Series 2. So a proper S1 horn button, or a a metal cup inside should fix it?

OK, John, here are a couple of pics I found to demonstrate what I was referring to:

Series I button with chrome trim ring:

Back of Series I button (with metal contact point):

If you don’t feel like taking out a second mortgage to buy a correct button, you could modify yours. Figure out a shell casing size that is roughly the size of the button on the top of the rod, and cut it so it’s the same length as the rod button (22 might work). Solder a short chunk of copper wire to the casing. Attach a screw terminal to the other end of the wire. Drill a small hole in the recess in the button’s contact and screw the wire to the button.

Place the new shell casing slip contact on top of the rod button, and put the button in place on the wheel. With any luck the slip contact stays in place and conducts power to the wheel when pressed. It would be more reliable if you could just solder the wire to the rod, but then the wire would get tangled as you steer.

From your pic it looks like the steering wheel spokes are polished. If so, then you do have the correct wheel as the Series II wheels weren’t polished but rather had a satin finish on the spokes. Yes, that and your blacked-out horn button were all part of the US federally mandated safety measures to keep us from being “blinded by the light!” There were many other mandated changes too but those have been covered elsewhere on this forum. Cheers.

Spoken like a true Texan! Make sure it is a spent .22 round and not a live one like the guy put in his car’s fuse holder when the fuses kept blowing.

I remember a carpenter from Texas explaining his technique for quickly creating 1/4", 3/8" and 1/2" holes in plywood without needing electricity for a drill.

I love America. That something like that should be a common household item is a thing of amazement to Australians.

Well it’s not common for me, but it is Texas so there’s a range in every direction.

For the record, a proper S1 horn button with the metal cup inside fixed the problem. Thanks Guys!

It used to not be the case. Back in 1980, I designed and manufactured a centre fire, target rifle. I had no borrowings from this bank, but a friend of mine was the manager of this particular branch. Upon completion of the first of the production run, I happened to be passing his bank and I called in to show him the completed item. I walked straight into the bank and into his office with the rifle, without any one not more than blinking an eye.

On another occasion, at the completion of a state target shooting championship, on my way to the airport for a flight home, I had the taxis driver stop at a shop so that I could pick up a rifle bolt action. When boarding the aircraft, the bulky action that I had stuffer into my coat pocket, fell out and rolled down the aisleway without anyone giving a hoot.

Nowadays, both of the above events would see you locked up and the key thrown away, if not shot full of holes. ![]()

Regards,

Bill

Thanks Erica, you gave me a gut laugh there, makes me imagine car jacking your E-type would be “risky”

I was doing some fencing recently at a 1940s Housing Commission house, had to cut some of the old posts out with an angle grinder, and big pile of 22 bullets were packed into the hollow posts, (which reminds me I better get rid of them as you can be jailed for years for possessing ammo). An older fellow said some of the previous occupants were bad buggers ![]() I will keep a couple for Jaguar repairs

I will keep a couple for Jaguar repairs ![]()

hope you dont mind if I later post up a very specific picture of an inner column with one very specific technical question, which I am sure you will know the exact (yes or no) answer, I will call out your attention as I did here, but put it in the other overhaul post you commented in