No, the forward motion of the wheel prevents them from becoming loose - they are notionally “automatic locking” hubs in that they they lock where you leave them, not get tighter with use. You set how tight you want them and they stay that way. I did a bit of research on this urban myth.

As Donald Bastow (ex-Rolls-Royce, ex-Bentley, author etc) looking at the Rudge Whitworth design expressed it when asked if they were self tightening - “perhaps more importantly, not self-loosening”. So if one does become loose it will not fall off although how it would come loose in the first place given they are not supposed to I am not sure. The ‘miracle’ of a self tightening nut was a product of the R-W advertising back in the day (although even they were careful to say “It is then impossible for the nut to work loose”), is quoted directly in modern texts without qualification or support and so the legend lives on.

I found this explanation of the way the Rudge Whitworth hub works but I am no wiser as to whether it claims it actually tightens, remains were it was set or does not self-loosen. And if it does tighten, how much torque can be applied in this manner:

“In its essentials the Rudge-Whitworth wheel comprised three key components: a splined hub and two pairs of matching tapers (conical surfaces), one comprising the inboard end of the hub and the inboard wheel centre, and the second the retaining nut and outboard wheel centre. These tapers served three functions. First, they automatically centred the wheel on the hub. Second, they transmitted a significant fraction of the drive and/or braking torque so as to reduce the load on the hub splines. And third, they made the wheel-retaining nut self-tightening. Imagine that the nut loosens slightly so that the tapers on the wheel and nut touch at only one point on their circumferences. Because the male taper is now of smaller effective diameter than the female taper, rotation of the wheel on the hub under braking will cause the nut to rotate on its thread. If this rotation is in the correct direction — which is ensured by using differently handed threads on either side of the car— then the nut will automatically re-tighten itself.”

This is from the Rudge Whitworth article which explains the system as “self-locking” - the cone centres the wheel and the spinner self tightens but requires a spanner or hammer to get it to that position. I think that is possibly where the confusion comes from - the spinner does indeed self tighten but only does so when whacked with a hammer:

Here is another explanation of the Rudge Whitworth hub which seems to confirm it:

In 1913 the Rudge Whitworth coned locking device was introduced. The parallel splines are a loose fit on the inner hub and a proportion of the car’s weight is carried by the nut itself. The nut tightens on the male coned surface of the end of the outer hub, and has a mating female cone machined in it. If the nut is loose there will be a gap between these two cones, allowing the wheel to wobble slightly. The car weight will now be carried at a single line of contact between the coned surfaces of nut and wheel. As there is a gap between the cones, the effective diameter of the cone on the hub is smaller than that of the nut.

The line of contact therefore rolls relative to hub and nut as the car moves. This, the theory says, can be likened to an epicyclic gear. In this arrangement, with the planet gear (i.e. the outer hub) rotating, and the planet carrier fixed (i.e. in this case always vertical), the outer gear (i.e. the nut) will tend to rotate backwards. By placing left hand threads on one side of the car, and right hand threads on the other, this tendency is used to tighten up the nut. The weight is also carried by the threads at the bottom of the nut, and the relative motion between the nut and the inner hub induced at this point is in the same direction, and also adds to the tightening action. Once the nut has tightened, the clearance between the cones is taken up and the rolling action stops. (my underline).

So confident were Rudge Whitworth of this theory that one of their patents describes a nut in which ball bearings are added to enable it to tighten itself more easily. It was only necessary to fit the nut hand tight, and after 1/2 mile or so (forward) it would require a spanner to release it.The early Rudge tapered‑cone wheel nuts were circular, and were removed with a special spanner. I don’t believe theories like this so I always knock my wheel nuts up tight, especially on the wheels with dodgy splines.The knock‑on ears did not appear until much later.

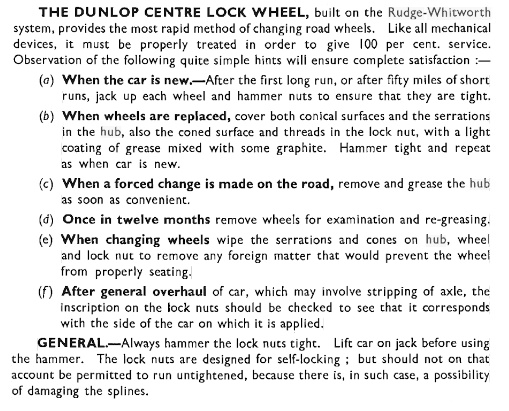

Here are the Dunlop official period instructions on the use of Dunlop Rudge Whitworth pattern hubs:

I am prepared to be educated if anyone can come up with a plausible mechanical or scientific explanation of how two masses rotating in the same direction can tighten beyond 220lb/ft rather than remain static with relation to each other. Also if the system is self tightening just how does the spinner come loose so it can self tighten again?

Interestingly, and something I did not know, after Rudge Whitworth went bust in 1936 Jaguar acquired the rights to Rudge’s wheel business and together with Dunlop continued to exploit the design for both wire and disc wheels although by then the system was termed ‘fail-safe’ rather than self-tightening.

David

ball. Just sayin’. Paul

ball. Just sayin’. Paul