49 degrees does seem like a lot of advance for a 12.5:1 CR engine, doesn’t it?

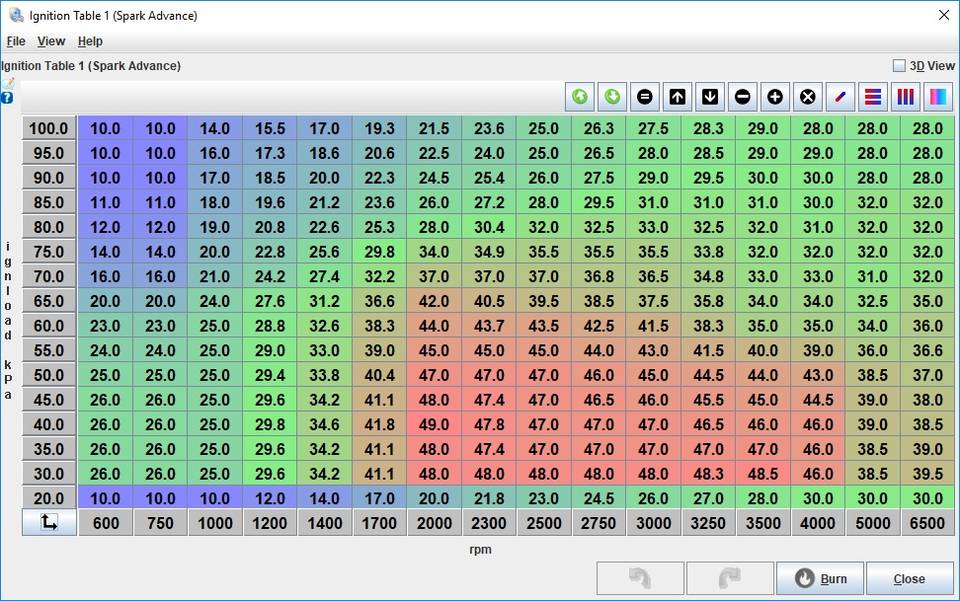

Its not that complicated really… the vertical line is Ignition load and the load i usually the MAP reading…100 will be WOT, the 20 line will be over-run or engine breaking or what ever you call it. in my case the engine idles at 35 and cruising at about 45-55…

I ended up with about 40 degrees at cruising, no pinging or stumbling… you can do this running a lean AFR wich will burn slower hence the numbers

Outside temp today around 20 degrees C so airtemp a fair bit down compared to my last tuning runs…I still have a inlet air temp of 60-65 degrees C so cold air intakes will be made as well…

So, no units in particular, just a 20-100 scale?

So, you retard the timing on overrun? Does that help prevent backfiring or something?

Ah, that makes sense!

Gee, your chart looks more like 45-47 degrees at cruising.

Yep, the vertical scale is engine load from 20% to 100%. When using manifold pressure, this equates from 20kpa (high vacuum) to 100kpa (wide open throttles, no vacuum, barometric pressure).

I’ll answer more comprehensively tonight when I have more time (unless someone else hits the nail). For now, just a hint: “Ported vacuum”

The system will always use a evarage of 4 cells so its never one single cell that will be in charge.

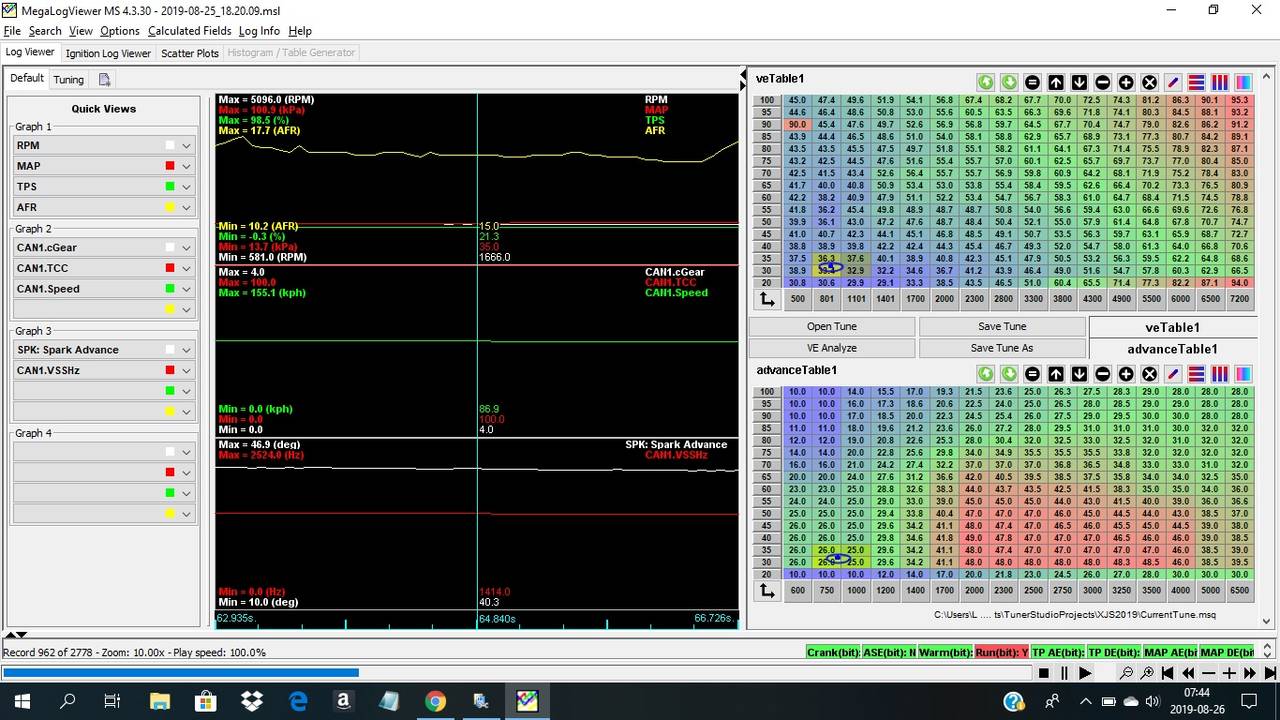

The everage wil be depending of the “cell weihing” so depending of where the “Map Dot” (the actual reeding of the MAP signal) is located in the 4 cells it will calculate the output ignition timing… not so easy to describe in words but you can see it in the screenshot below.

I can see from my log files that at 90km/h I have a map signal of 35Kpa, 1670rpm, and a ignition of 40degrees.

So according to my log file it take 12.7 second from 40km/h to 155km/h, not so bad  just need to move up the shift point of the transmission a bit…

just need to move up the shift point of the transmission a bit…

Kirby, you may recall my “class-action” thread (Ported vs Manifold) on the matter of “Ported vacuum vs Manifold vacuum” supply for the vacuum advance module of a distributor.

In that thread I stated that one of the few benefits of ported vacuum supply (in contrast to the many downsides of ported vacuum), is that you will have more engine braking on overrun. The low advance values in the 20% row is the EFI equivalent of Ported Vacuum (On overrun). By DELIBERATELY making the engine INEFFICIENT on overrun, it requires more energy from the wheels back into the engine to make it turn, thus implementing more engine braking on overrun.

By making the 20% (KPa) row the same as the 30%, would result in less engine braking. Never tried to find out how much less.

One of the main benefits of “Manifold vacuum” supply for the vacuum advance module was that full vacuum (and hence timing advance) is applied at idle (to make “idle” also as efficient as possible). On my timing map you can see “Manifold vacuum” implemented at idle by looking at the 800 & 1000rpm collumns and the 30 and 40% rows (where “idle” is) where 25º is applied for idle, vs 10-14º at full throttle at 800-1000rpm. So, with this mapped ignition solution, I have the best of both ported and manifold vacuum.

The reason for ported vacuum – other than keeping cats hot for emissions reasons – is to avoid an idle instability. The early H.E. tries to get the best of ported and non-ported by utilizing a vacuum modulator to provide some vacuum at idle but to hold it steady to avoid instability.

I dunno how you avoid idle instability in your digitally-controlled engine, but I presume it hasn’t been a problem – possibly because you don’t even get to the 20 area of the map at idle. Thing is, though, I guess you care more about engine braking than I would. If I wanna slow down, I use the wide pedal.

BTW, most modern OEM EFI systems shut off the fuel on overrun, so timing makes no difference. You don’t do that?

very interesting posts, if i didnt have my old system i sure i would use the MS units, many nice ideas,(course EFI has come a long way since 1995).

one thing i play with SDS, is on overrun slowing , i can shut off fuel, and just add a touch of fuel , makes an attention getting snap/and popping in exhaust , some like it some dont but a slight turn of mixture knob does it or quiets it,yeah, i know silly stuff, but part of the FUN of engines!!

roncenter%20consol%20J%20-bond%20system%20002|640x480

For sure yo can cut the fuel at over run, a lot of settings here as well… I dont use is at the moment and I think its here that many get in to problems, adding to many features at once… get your timing and fuel dialled in first than add additional features… and there are a lot of fun things in there to add, to many to mention but more to read here, Megasquirt3_TunerStudio_MS_Lite_Reference-1.5

Not all Megasquirts are equal. When Philip put that map together, using MS2, overrun fuel cut was not available as an option. Tobbe is using MS3 which has many new features added, including how to cut out and cut in the fuel and spark.

What is interesting is that modern fuel injection systems started by mimicking carburettored engines, so people with MS systems can often see the cause and effect (and solutions) for lots of engine maladies simply by playing with the settings and looking at the datalogs.

For example, to get a more stable idle, Kirby could deliberately make his ignition map have a little depression in it around the idle point, so when the car stops, the engine tends to not want to race away or hunt, but will sit collared, retarded slightly about that point. Once the throttle is opened and rpm is above idle, the car “goes” because the map jumps to a cell where it has more advance. MS3 even allows a separate idle map which automatically engages under certain conditions, e.g. throttle closed, speed zero. At one point, I experimented with running a super lean idle so it didn’t waste fuel when standing at a stop light. It ran very hot, but used only 2/3 of the fuel that would have been normal.

kind regards

Marek

As far as I’m concerned, I have not found any such idle instability, and I use all the advance the engine wants on all my projects.

Correct. Idle happens in the 30 - 40 area of the map. Only overrun at higher revs get one close to 20kpa manifold pressure.

ECU can do overrun fuel cut and I have experimented with it before. Of no measurable consequence in my book.

This particular engine has a performance camshaft and idles at ~980rpm and 49kPa manifold air pressure (MAP). The darkness of the cells is a measure of how many times it was in that cell, so you can see that most of this journey (the steady cruising) was done at around 1700rpm and 62kPa.

Of note is that the car never goes into the bottom left corner of the map - it’d have to be running downhill, very slowly and at very low revs and that simply never happens. Thanks to the gearing, on this journey, the engine never got above 3000rpm. It’s a perfect example of why fitting an aftermarket performance camshaft may be a total waste of time. Note also how laboured the idling is with a performance camshaft - the other engines quoted consider idling a much lighter load as reflected by their idle point being lower down the y-axis in the table.

The third parameter plotted is air:fuel ratio. It’s lean at or below the cruise region and richer at or above idle. The more heavily loaded the engine is, the richer it is set to run.

kind regards

Marek

Same car, different journey. Here is a plot of how open the throttle is at different rpm and engine loads. On average the throttle is closed where the idle region is, where the overrun is, but is ~28% open when cruising and ~50% open when heavily loaded at medium revs.

Just for kicks, here is the average “bottom of the radiator” temperature for the same journey.

kind regards

Marek

Thanks for that RPM vs MAP vs TPS histogram Marek.

I’ve been saying many times on this forum that as little as 30% throttle AT IDLE SPEED, puts the engine at or near “100% load condition” (same as full throttle).

Your histogram shows this very clearly.

That’s logical. For a correctly sized throttle body, you’d hope that 6500rpm and 100% loading corresponds to a 99% open throttle (the top right hand corner - full power !!), so when going at half that rpm, the throttle needs to pass half the amount of air in the same time, so will only need to be half open.

The radiator coolant map shows that the radiator isn’t being used much most of the time as the temperature is nowhere near the mid 70’c range. The corresponding coolant map showed ~80’c over almost the entire grid.

kind regards

Marek

Blockquote

Which also confirms why standard fans are more than adequate. No need for “high power” fan upgrades on a properly sorted cooling system (and engine being well fueled and timed).

That is correct and in MS3 you can actually set what is considdered as WOT vs. rpm used for accel enrichment-

This curve sets the TPS% that is considered wide-open-throttle based on RPM.

i.e., at low RPMs, partial throttle will flow the same air as full throttle. At maximum RPMs full throttle is required for full air flow.

When the throttle is at, or beyond, the new ‘full throttle’ it is considered to be 100% throttle. This has the effect of making TPS based accel enrichment more sensitive at lower throttle opening at lower RPMs and also prevents TPS accel enrichment if the throttle is already ‘fully open.’

Scatter plots/ histograms are a very good tools to use looking at the data logs, tells you where to spend your time in tuning the maps

Hi Marek

Interesting data logs!! One interesting fact is that a simple butterfly valve is not a very good flow control valve for accurate flow control…but is “close enough” for a car. It is non linear and reasonably sensitive at small opening angles to flow increases. Probably not worth fretting over unless you are trying to use throttle position with respect to flow in some fashion.

How do you generate the scatter graphs???..Edit…sorted…MegaLogViewer…

I’ll have to learn how to use this…driving with the laptop open beside me is a recipe for disaster…![]()

![]()

Regards

Matt