Hi, all…A good friend of mine is working to get his XK120 coupe engine in shape. Part of the minor overhaul requires the replacement of the crankshaft bearings and con rod bearings. The engine is on a lift with the oil pan already removed, providing access to do the job correctly. Parts are in-hand. So it’s just a question of labor.

My question is: how long, in hours (not beers) do you think it should take to accomplish this ? (note: my fear is that he may be getting overcharged by a local mechanic who estimates 37 hours of work to achieve what I’ve described, above ( !! ).

Thoughts and opinions appreciated.

Seems to me the mech wants to pull the tranny to replace the main shells…37 hours!

Mechanic claims he can do everything as it sits on the lift ( which is true). No discussion about pulling the tranny…or anything else. That’s why I’m scratching my head on how he’d spend all that time.

The 120 has no rear main seal so I don’t see why the crank can’t just have it’s upper shells rolled into place. The front seal should have enough “give” to allow upper shell installation.

Checking the new clearances would require that the crank be forced up into the new upper shells in order to use plastigauge on the lowers.

I know it’s done, but this sort of thing makes me squeamish. I like to at least polish the journals and check for ovality before I stick new bearings on an old journal.

You can check the rod journals. The mains can’t be done unless you drop the crank. You can instead plastiguage in two places. If the squish is the same… good 'nuf. This isn’t supposed to be a grand-scale rebuild.

And no adjustment shims to deal with!!!

![]()

Thanks, Mike…I tend to agree with you. Don’t know how old this engine block is, as it’s not the original to the car. So if it were me, I’d pull everything out.

Thanks, Mitchell…I’ll pass this along with the other posts.

i have changed the bearings from bottom of car without rebuild or removal on "57 140 ots in about 6 hrs for that part of job in a small garage of friends visibility is good and access easy .getting at cracked oil pump rotor and figuring out what had done it and cleaning that huge tin sump on the spot probably took more time. j

The first car my father owned, purchased with money he saved from his US Navy paycheck during WW2, was a down-at-the-heels 1937 Packard roadster. According to family lore, he was on his way home from visiting his older sister, who lived about 95 miles away, when the Packard developed a loud rod knock. Supposedly, Dad, who was definitely NOT a hands-on car guy, dropped the sump on the side of the road and replaced the blown out bearing shell with a piece of leather he cut from his belt, and drove 50 miles home.

I cant see how it would take a pro mechanic 37hrs to do this job…unless he has never done this job before (which would concern me). Even then, I cant see it. The only thing I could think to do is politely ask him for an approximate breakdown on why the time is so long ( after you have consulted with forum people).

Does the 37hrs include all the hours he is charging for all work on your car up to this point, and any other work ?

Is he allowing “contingency” time ? (like most builders do in a quote)

back in the day, I believe there existed bulletins for dealers for time on certain jobs, if anyone would have access to these bulletins, I suspect @Roger_Payne would be the person…sorry if I am wrong about that Roger

More information needed, really.

How do you know the mains and big ends need replacing? What kind of measurements have been made, and how? Why do they need replacing - foreign bodies, wear and tear, scoring or copper showing through?

Early XK motors are getting rare and expensive these days, so I wouldn’t take any chances and would prefer to do the job properly. At best, the journals should be polished.

edit - I suppose it’s always possible the 37hrs includes time to remove the engine to inspect and measure the crank properly, in which case that’s fair enough.

He would have had to contend with poured babbitt bearings. That would certainly quiet the knock, but not for long. He might have caught a bit of inspiration and pulled that spark plug lead. But… it’s hard to imagine that all of the tools required would have been at hand including a change of clothes.

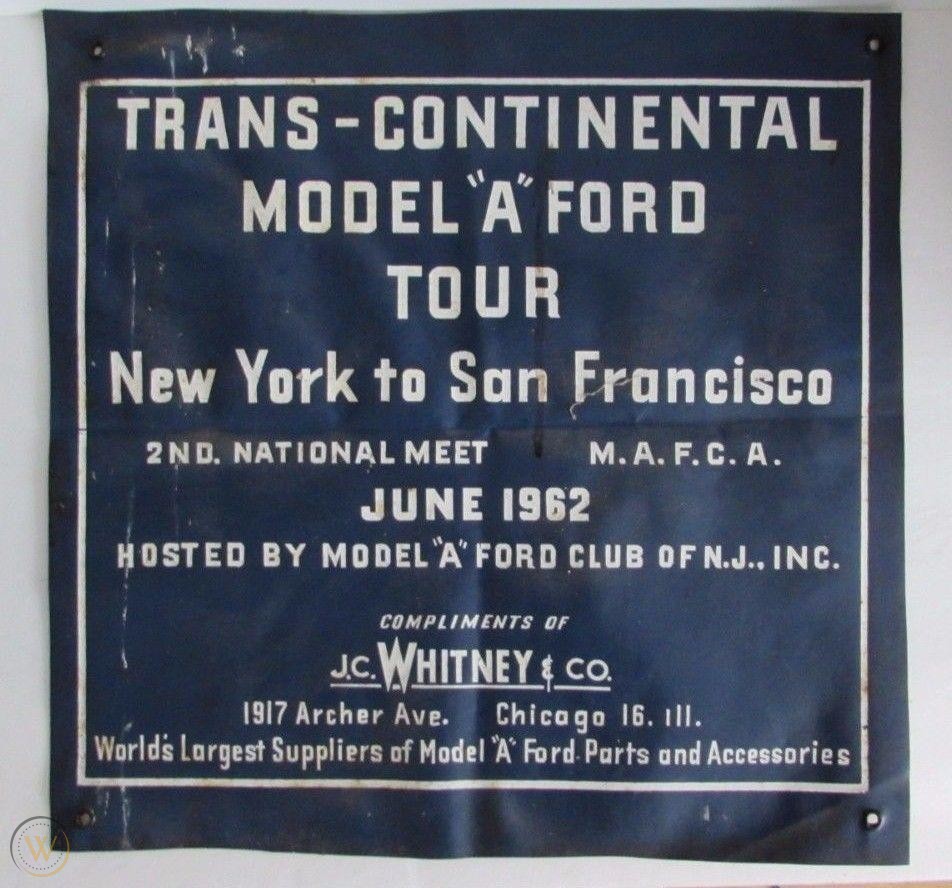

My Model A Ford club made a cross-continental trip from NJ to CA and back in '62. They had a parts and tool truck follow long as sweep. They used both spare engines swapping them in motel parking lots along the way. I joined just ten years later and heard the tales including the tudor that rolled in New Mexico and made it to CA and back to NJ with it’s doors tied shut. It landed on it’s wheels but they laid it on its side and jumped on it the re-align the upper body.

Ah… J.C. Whitney & Co.

As you can guess by the responses, rod bearings can be done this way easy enough, but most of us would not do main bearings this way. What makes you believe you need new main bearings?

There will be a number stamped by the oil filter. If you give us this number we will know where the engine came from and can give you better advice.

Thanks, John…the consensus seems to be that’s it’s definitely possible. The question becomes: is it the right thing to do under the circumstances, i.e. what does my friend know about the overall engine condition, what makes him think it’s necessary, etc.

Ahh ! It was Rob !

Here’s the response from my friend:

Harold:

The engine number is A2384-8 and is from an early Mark VII. Thanks again for your help.

Dave

Harold J Kelly

12235 Lashbrook Ct

Jacksonville, FL 32223-4800

904-401-8228

![]()

February 8

HJK:

Don’t know how old this engine block is, as it’s not the original to the car.

As you can guess by the responses, rod bearings can be done this way easy enough, but most of us would not do main bearings this way. What makes you believe you need new main bearings?

There will be a number stamped by the oil filter. If you give us this number we will know where the engine came from and can give you better advice.

At least, in a T or A, one can pull the piston out and down, past the crank, crocus up the crank, and put in a newly-babbitted rod, available from the aforementioned Warshawsky’s…

Dave is correct that an A prefix engine is from a Mark VII, and would be from 1951, in fact the 1384th Mark VII engine to leave the engine assembly line. Its pretty much exactly the same as the equivalent year XK120 engine except for camshafts, distributor advance and carb needles. And the front engine mounts we were discussing in another thread. You might encourage him to join our forum.

I still have a bearing scraper around here somewhere. You work in a slim pool of oil so you can see the meniscus form along the edge of the tool to tell that you’re level to the surface. …fun.