Just recording for posterity some observations about the wiring harnesses for Mark V.

Previous models have the main wiring harness from the firewall (scuttle) to the trunk (boot) running along under the chassis frame, and held on by a number of clips. It is fairly easy to install, but is exposed to weather.

So for Mark V they decided to run the harness through the door sill. I believe this was the first model where they had a boxed-in steel structure as the sill. Anyway it would be protected from weather in there.

The installation is really two problems, the door sill and the dogleg.

The factory installers either left a piece of string or wire in there as the body was built, to pull the harness through later, or maybe had a 6 foot (2 m) long stiff wire with a hook. They probably did it after paint but before the fenders (wings) were on. There are a couple of restrictions on a saloon, one on a DHC, the boxed in door opening stops. The harness has to pass those. Also a short stub wire has to be pulled out at the switch hole in the door sill, so there must have been a second wire or string from the front through the switch hole.

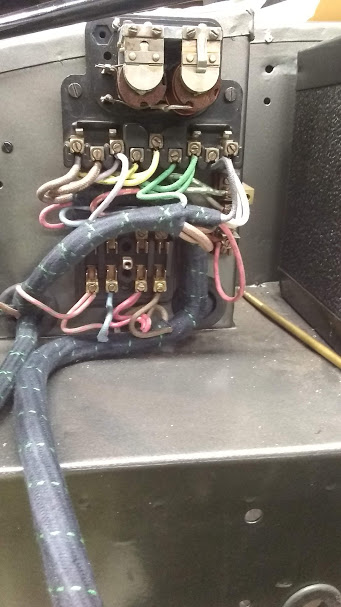

The new harness has a number of individual wires hanging out of the cloth wrapping in places, and exiting the wrap pointing to the rear, the pulling direction. From years of watching pro electricians pulling wires through conduits at my lab, I learned the trick of bundling wires together with tape. Also there are some rubber covered bullet connectors on the harness, which I removed so they would not fall off inside the sill. In one place there are seven bullet ends together, so you want to wrap those with tape, and don’t fold them back, wrap them in the pulling direction with the other bundle, so they will go up the dogleg.

I tried 4 times to push my harness through from the front, no luck, it bunched up inside. So I got a piece of stiff wire through from the front, and it was easy to get it out the back end which is somewhat open. Hooked the harness to this wire and pulled it in. Places where a large bundle is passing the door stop boxes, you just work it back and forth until it goes through.

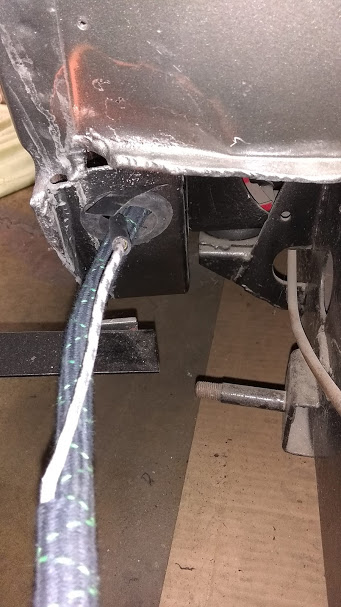

At the dogleg, the harness turns up and fits through a place where the inner fender and sill meet, then up past two caged nuts that hold the rear wing on. Here is where the 7 bullet ends get stuck on the caged nuts, so keep that bundle on the inboard side and the smaller bundle outboard. There should be a plastic sleeve on the harness, that ends up at this dogleg, to protect the harness from the weather and road dirt there. You want to get the end of the sleeve up into the body at least to the floor level.

The saloon harness then splits where one longer tail runs up and across to the rear of the sunroof where there are clips for it, and over to the left rear interior light. DHC is similar but runs along below the convertible top. There are wires that feed off to the trafficators in the saloon center posts or DHC sides if you have them. If your car is a USA delivery and doesn’t have trafficators, these wires are not used and should be protected so as not to touch the body. The shorter tail has connectors for the trunk harness.